Scanner accelerates production of toilet bowls

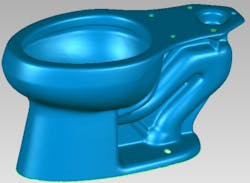

Engineers at NVision (Coppell, TX, USA) have helped a manufacturer of bathroom fixtures produce the path for a robot to follow while spraying enamel on the exterior and bowl surfaces of a new product the company is introducing.

Toilet bowls and tanks are made from vitreous china, which is a special mix of several different kinds of clay. During production, toilets are glazed at the manufacturing facility to prevent bacteria growth in the bowl, which can create health hazards. The manufacturer has automated this process, using a robot to glaze the bowl surfaces with an enamel spray.

However, engineers first need to program the robot's path by inputting the parameter's of the robot's motion into a CAD model of the toilet.

Since a CAD model of the toilet bowl and tank combination was not available, the manufacturer hired NVision to create one. To do so, NVision engineers drove to the manufacturer's plant and, using a Z8 HandHeld scanner on a 9ft arm, scanned a number of one-piece toilet bowls and tank combinations.

The NVision handheld scanner is a portable scanning device that is capable of capturing 3-D geometry from objects. The scanner is attached to a mechanical arm that moves about the object, freeing the user to capture data rapidly with a high degree of resolution and accuracy.

As a part is inspected, the scanner generates a point cloud consisting of millions points each with x,y,z coordinates and i,j,k vectors. Integrated software that comes with the scanner is used to convert the point cloud to an STL polygon file. The software provides real-time rendering, full model editing and polygon reduction, and outputs data to all standard 3-D packages.

Scanning took only four hours for five bowl/tank combinations. "We had to be very careful when handling the parts as the base clay was unfired and therefore fragile in nature. The biggest challenge was capturing the geometry of the underside of the lip around the bowl interior," says NVision engineer Colin Ellis.

Approximately two days after scanning, NVision delivered the data to the manufacturer in an STL format. The STL file was then converted to a CAD format for programming the robot path and the manufacturer began production of the new product.

Related items from Vision Systems Design that you might also find of interest.

1. Laser scanning - It's not just a flash in the pan

A manufacturer of toilets for corporate jets has used a laser scanning system from NVision (Coppell, TX, USA) to reduce tooling costs and get a new toilet design to market faster.

2. Laser scanning and 3-D printer help sculptor reproduce his work

A Santa Fe-based master stone sculptor is using a laser-scanning service from NVision (Coppell, TX, USA) to enable him to capture and save his work as computer models, which can then be used to reproduce the sculptures at any size on a 3-D printer.

3. Laser scanner enables 3-D modeling of key impellor at hydroelectric plant

The turbines that move the water in hydroelectric plants employ massive impellors. Facing an extended shutdown due to a faulty impellor, a major hydroelectric facility looked for assistance in creating a 3-D model for a replacement part.

-- Dave Wilson, Senior Editor, Vision Systems Design