Imaging system spots defects in glass fiber reinforced plastic parts

Researchers from the Department of Electrical Engineering at the Universite Laval (Quebec, Canada) have compared several imaging techniques to determine how effective they are at spotting defects in Glass Fiber Reinforced Plastic (GFRP) -- a plastic material reinforced by fine fibers of glass that is widely used in the aerospace industry.

Several types of defects may appear when manufacturing GFRP such as delamination, porosity, undesired inserts, and material discontinuity.

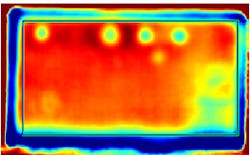

To determine how effectively they could be detected by near/shortwave infrared, ultrasound thermography, and optical pulsed/lock-in thermography, the researchers examined specimens of the material supplied to them by the Centre Technologique en Aerospatiale (CTA; Quebec, Canada).

The results showed that the near infrared inspection technique had the best performance out of all of them. Using near infrared inspection, the researchers were able to observe all of the defects, except delamination. They also discovered that only the ultrasound thermography technique was capable of detecting the delaminations located in the edges of the specimens.

The researchers detailed the results of their study in a paper "Inspection of Glass Fiber Reinforced Plastic (GFRP) using near/shortwave infrared and ultrasound optical excitation thermography" which was presented at the International Workshop on Smart Materials, Structures and NDT in Aerospace in November last year.

A copy of the paper can now be downloaded from the Internet here.

-- Dave Wilson, Senior Editor, Vision Systems Design