Deploying Industrial Dashcams for Real-Time Process Monitoring in Manufacturing

Dashcams, increasingly popular as evidence tools in traffic accidents, are mounted on vehicle dashboards and continuously record traffic events in a loop. In case of an accident, the recording stops after a set duration, providing video sequences that capture the moments just before and after the incident, helping to determine fault.

The Importance of Monitoring Industrial Processes

Even in industry, unexpected disruptions can have a significant impact on the production process. Quickly and effectively resolving these interruptions requires a clear understanding of their root causes. Often, sudden machine breakdowns, issues during material or product handling, or recurring process errors cannot be easily explained. These issues frequently originate from inaccessible areas, complicating the troubleshooting process.

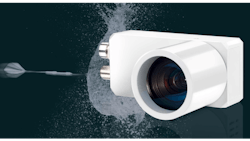

The development of industrial dashcams adapts the core concept of vehicle dashcams for industrial applications. The recording of an incident is triggered by a sensor or a PLC signal, ensuring that only relevant video sequences are captured. With high-resolution video recordings, these cameras enable detailed offline and slow-motion analysis to accurately trace processes and identify the root causes of disruptions. Both the configuration and playback of recordings take place directly on the smart camera itself, eliminating the need for additional external systems.

Unplanned Downtime is Expensive

- For the world’s 500 largest companies, unplanned downtime equalsS 11% of their revenue, or a total of $1.4 trillion.

- The average plant loses 27 hours a month to unplanned downtime

- The cost of one hour of downtime has doubled over five years.

Source: The True Cost of Downtime 2024, Simens: https://assets.new.siemens.com/siemens/assets/api/uuid:1b43afb5-2d07-47f7-9eb7-893fe7d0bc59/TCOD-2024_original.pdf

Versatile Applications: From Fault Detection to Optimizing Machine Setup

Industrial dashcams are versatile and not confined to specific applications, making them suitable for any setup involving moving products or materials. For instance, they can be deployed in packaging machines that handle films. The risk of sporadic film tears increases with thinner packaging materials and faster processing speeds. If a tear occurs due to poor material quality or machine wear, it often results in extended downtime for clearing debris, diagnosing the issue, and restarting the system. When such systems operate worldwide and on-site personnel lack the expertise to handle complex issues, industrial dashcams enable rapid identification of faults. By documenting events—accessible remotely—in real time, experts can quickly and clearly diagnose problems without costly on-site visits. This detailed documentation benefits quality management and significantly enhances system efficiency.

Related: Monitoring Critical Infrastructure with AI-Based Computer Vision

A second application example relates to frequent product and batch changes, driven by shrinking lot sizes and higher production speeds, which often results in increased waste. For instance, in the packaging industry, products and packaging must be synchronized. As the variety of packaging formats grows, configuring machines becomes more challenging. This issue is evident in the production and packaging of chocolate bars, where each bar is individually wrapped in film and then collectively packaged in boxes or multipacks. Industrial dashcams provide engineers with a powerful tool to check synchronization and configuration, ensuring smooth operations and reducing waste. Even during ultra-fast movements, these dashcams capture precise insights, helping to identify optimization opportunities.

Recording Footage for Error Analysis

Industrial systems often operate seamlessly for days before errors occur randomly. With their storage and trigger functionality, industrial dashcams capture short, meaningful video sequences around the error event without generating unnecessary recordings.

Similar to dashcams in a car, industrial dashcams continuously record and overwrite video data. When triggered by a connected sensor, such as a distance or laser sensor, or by a PLC signal, the dashcams save a sequence capturing moments before and after the event, depending on the configured mode. This flexibility allows users to record the perfect footage for error analysis.

Related: Minimize Downtime with Condition-Based Monitoring

In some scenarios, a "heartbeat" mode can trigger recordings. Here, the PLC sends regular signals to the smart camera to indicate normal operations. If the signal stops, the dashcam captures sequences before, during, or after the missing signal for analysis.

For specialized applications, an AutoTrigger mode starts video recording based on integrated image processing algorithms that detect changes exceeding predefined thresholds. While highly effective, this mode depends on the scene and requires application-specific expertise and additional software functions.

Video Compression

Recording high-resolution videos generates significant data volumes, which are challenging to store or transmit effectively in compact devices. Industrial applications often restrict the size of camera housing due to accessibility constraints. To address this, industrial DashCams feature video compression technology, allowing efficient storage on compact media without requiring an external PC. These videos can be easily transferred to various devices via web browsers and played back with standard software.

Efficient Error Analysis: The Advantages of Industrial Dashcams Over Conventional Solutions

Industrial dashcams set new standards in condition monitoring, offering significant advantages over traditional condition monitoring technologies such as surveillance cameras, thermal imaging cameras, vibration sensors, or purely software-based solutions.

Unlike conventional surveillance cameras, industrial Dashcams provide precise, high-resolution video sequences tied directly to the moment of error, eliminating the need for time-consuming video searches. Equipped with global shutter sensors, industrial Dashcams also capture sharp images of rapid movements, a capability lacking in surveillance cameras with rolling shutter technology. This makes industrial Dashcams indispensable for high-speed processes.

Thermal imaging and vibration sensors, while providing specific data, lack the visual insight into fault scenarios. Industrial Dashcams deliver high-resolution visuals that are crucial for effective error analysis. Unlike complex software solutions, which require significant initial investments and setup time, industrial Dashcams operate in real-time and integrate seamlessly into existing processes.

Related: Keys to Deploying Machine Vision in Precision In-Line Measurement Applications in Manufacturing

High-Speed Recordings

Industrial systems often operate at extremely high speeds, where standard frame rates may be insufficient to capture and analyze rapid movements accurately. Advanced hardware and software technologies enable high-speed Dashcams in compact industrial smart camera formats, supporting HD video recordings at up to 1,000 fps.

Industrial Dashcams provide an effective solution for precise process recordings and analysis, supporting fast error detection, condition monitoring, and documentation. They enhance the efficiency of service operations, reduce system downtime, and minimize operating costs. Complemented by intelligent sensor systems and embedded vision solutions, industrial Dashcams enable automated analysis of mechanical movements, driving the optimization of industrial processes.

About the Author

Christoph Siemon

Christoph Siemon joined IMAGO Technologies (Friedberg, Germany) in 2021 and has been part of the management team since 2024. He brings extensive experience in sales and project management from the automotive industry. As an industrial engineer, he is responsible for sales, marketing, and development—with a clear focus on customer-oriented innovation.