Vision system produces crack free billets

Suppliers to the automotive industry demand crack free billets of steel from steel makers to ensure that the products that they make from them are faultless.

To ensure that they are, steel makers need a way to test the surface of the billet and an efficient means to remove any existing cracks on them.

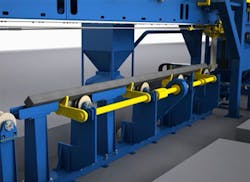

Addressing that need, engineers at Buck Materials Handling Equipment (Rotkreuz, Switzerland) have developed a system known as the Mecana NT that pairs a dry magnetic particle inspection system with an optical crack recognition system.

The data from the optical recognition system is used to direct high pressure grinding machines from SMS Logistiksysteme (Netphen, Germany) which then grind any cracks that are found on the billets. The combination of the two systems enables cracks to be detected and removed fully automatically.

The system is not only able to detect existing cracks on billets, but also reduce cracks through optimizing the casting and rolling processes. The Mecana NT system is currently in use in a German steel plant.

Details of the system were described earlier this year in a paper presented at the International Surface Inspection Summit ISIS in Mumbai, India by Daniel Aegerter and Jan Gummersbach. The paper from that conference is available here.

A video of the Mecana NT system is available on the Buck web site here.

Recent articles on surface inspection that you might also find of interest.

1. Machine vision evaluates surface roughness

Researchers at the School of Mechanical and Building Sciences at VIT University (Tamilnadu, India) have developed a machine vision system for evaluating the surface roughness of turned components.

2. Spotting defects in curved reflective surfaces

Researchers from the Toyohashi University of Technology (Toyohashi, Japan) have developed a vision-based inspection system that is capable of detecting defects on highly specularly reflective curved surfaces.

3. Vision robot inspects accelerator cavities

To optically inspect the surface structures of superconducting accelerator cavities, engineers at Deutsches Elektronen-Synchrotron (DESY; Hamburg, Germany) have developed a fully automated robot.

-- Dave Wilson, Senior Editor, Vision Systems Design