Snapshots

Adaptive optics tracks microstructures

In its conventional form, the optical microscope is a trade-off between resolution and field of view. A new optical-microscope design combines a high-speed steering mirror, a custom-designed scanner lens, a MEMS deformable mirror, and additional optics to enlarge the field of view while preserving resolving power and operating at a high image-acquisition rate to capture a mosaic of images. This adaptive scanning optical microscope is being developed by Benjamin Potsaid, a research scientist, and colleagues at the Rensselaer Polytechnic Institute Center for Automation Technologies and Systems (Troy, NY, USA; www.cats.rpi.edu).

The team has built a simplified prototype of the microscope using standard lenses from ThorLabs (Newton, NJ, USA; www.thorlabs.com), a Sony (Park Ridge, NJ, USA; www.sony.com/videocameras) XC-77BB CCD camera, Matrox (Dorval, QC, Canada; www.matrox.com/imaging) Meteor-II frame grabber, and a Texas Instruments (Dallas, TX, USA; www.ti.com) DSP-based board. A Boston Micromachines (Watertown, MA, USA; www.bostonmicromachines.com) μDM100 deformable mirror will be installed in the next-generation microscope to correct for optical wavefront aberrations.

The basic approach has been demonstrated in micro-assembly and biological observation tasks. In the first task, a shape memory alloy microgripper moves between two fixed objects in the workspace. The microscope automatically tracks the microgripper with a 3 × 3 image mosaic while also including the two stationary objects in the scan pattern, demonstrating the capability to nearly simultaneously monitor and track multiple stationary and moving objects within a workspace.

Edible printing is easily imaged

Ablating data onto fruit with a laser can result in the skin being vaporized and the product deteriorating. On light-colored citrus fruit ablation produces insufficient contrast to read or image unless enhanced by a food dye. To overcome these limitations, Sherwood Technology (Widnes, UK; www.sherwoodtech.com) has developed a system that uses a low-power CO2 laser to mark, but not ablate, fruit with high-contrast print containing data such as sell-by dates, country of origin, or product look-up codes. The company’s DataLase Edible technology ends the need to apply individual fruit labels, which may fall off or harbor bacteria.

After an edibile coating is sprayed on the fruit, the scribing laser images graphics on the surface of the fruit. The company’s “edible composition” can also be applied to pharmaceutical tablets and confectionary coatings.

Automation platform simplifies integration

Providing system integrators with the ability to integrate various application modules with motorized positioning tables or gantries and mechanical actuators, the new A3200 Automation Platform from Aerotech (Pittsburgh, PA, USA; www.aerotech.com) offers programming options for 32 axes of decentralized motion. This control is interfaced via a FireWire network with dedicated modules for HMI, PLC, and vision. The platform can operate in real time or under the Microsoft Windows environment.

Motion, HMI, PLC, and vision modules can be programmed in AEROBasic, RS274 G-code, C, C++, VisualBasic, Delphi, and LabVIEW. The image-processing module can be integrated at real-time level via a DLL and includes a processing tool for part identification and measurements using the MIL package from Matrox Imaging (Dorval, QC, Canada; www.matrox.com/imaging).

Typical applications include integrating a vision module with the motion system for use in laser machining, drilling, or milling systems.

AOI sees connections in 3-D

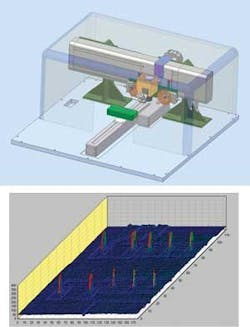

For automated-optical-inspection (AOI) applications, GÖPEL electronics (Jena, Germany; www.goepel.com) has enhanced its existing TOM Line inspection system with TOM 3D to provide additional inspection capabilities. These include checking connectors by inspecting for pin distortion, pin height, the verification of text-embossed or punched fonts-and measuring the solder or tinning volume at joints.

Using a CCD camera module combined with a laser, the TOM 3D assesses surface tomography by using laser scanning to generate a graph of position and height information that is combined with an image of the same location. As a result, both position and height of each pin on a device can be checked in a single operation. Plug connectors and solder joints can also be inspected. The TOM 3D can be configured as an in-line or stand-alone system. As a production-line tool, the equipment can be mounted directly above a conveyor or other indexing system.

System guides auto glass

Land Rover (Solihull, UK; www.landrover.com) has automated the assembly of automobile windows, moonroofs, and seals with vision-guided robots that use the SRS vision-sensor system developed by Oxford Sensor Technology (Abingdon, UK; www.oxfordsensor.com). The sensor system uses specular reflections to locate features on the vehicle body.

Six vision-guided robots from ABB (Milton Keynes, UK; www.abb.com/robotics) fit the glass, high-level brake-light assemblies, and part of the door seal to the Series 3 Discovery and Range Rover Sport vehicles. Four robots are dedicated to fitting the front, rear, and side windows, the other two fit the moonroof assembly and provide backup for the main glazing system. To glaze the windows, the robots position the window near the vehicle, and the SRS vision sensor determines the exact position of the aperture relative to the robot.