Board cameras aim at low-cost imaging

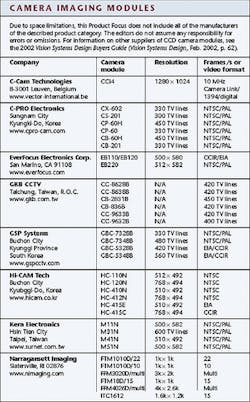

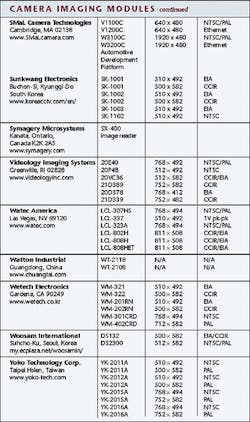

Board-level cameras based on CCD and CMOS devices are saving costs in various machine-vision, security, Internet, and embedded automotive systems.

By Andrew Wilson, Editor

Installed vertically on small printed-circuit boards (PCBs) and shipped without housings, board-level cameras are being used in a variety of machine-vision and image-processing applications. While many of these products are being imported from the Far East (see Vision Systems Design, Sept. 2001, p. 11), several US vendors are now offering similar products at comparable prices.

Many CCD- and CMOS-board cameras have been developed specifically for the video security market. They fit in an approximately 31 X 31-mm footprint and allow modules from various manufacturers to be embedded into different types of cameras. In choosing these low-cost modules for other image-processing applications, however, systems integrators must carefully consider their intended application. The application determines the choice of imager, resolution, lens, on-board signal processor, and video output.

Of course, pinhole-lens-based designs capture images that are lower in contrast compared to images formed by larger C- or CS-mount lenses. As a result, many CCD-board manufacturers offer several lens choices. In the design of its SJ 2350 1/3-in. interline 512 X 492-pixel, NTSC/PAL, color-board camera, for example, SJ Microtech (Kyungki-Do, Korea) offers several different configurations, including interchangeable pinhole and C-mount lens types. The C- and CS-mount lenses are approximately 1 in. in diameter and require more PCB area than the S- and X-mount lenses that are typically found in consumer PC cameras.

Automatic gain controlMany of today's CCD- and CMOS-camera modules are targeted at the low-cost security market, where they are embedded in broadcast-format, closed-circuit TV systems. To obtain images at varying light levels, these modules often feature on-board automatic gain-control (AGC) circuits that automatically set the exposure of the CCD or CMOS imager according to the captured light level. Panasonic's Industrial and Medical Group (Secaucus, NJ) implements this feature in its ZE-55171, 22 X 26 X 16-mm, color CCD-camera module based around an interline-transfer CCD (see Fig. 1). With an NTSC resolution of 768 X 494 pixels, this board-level camera features a 46-dB signal-to-noise ratio (S/N) without AGC and an additional 18 dB with AGC.Although this feature is useful in security applications, where uniformly consistent illumination is generally present, it may not be useful in scenes that contain both very bright and very dark areas. In such cases, the AGC circuits can often overcompensate for gain as they average the illumination levels. By compensating for the light areas in such images, the AGC closes the aperture that decreases the amount of contrast in the dark areas of the image. In machine-vision applications, which use uniform illumination to present consistent images to the imager or camera, AGC may not be required.

By implementing such functions, illumination compensation may result in inconsistent results when images are captured or processed. Accordingly, a number of CCD-board-level camera vendors offer systems integrators the option of enabling or disabling the AGC circuits. Sensor Technology America (Carrollton, TX), for example, offers a 0.5-in. interline CCD module with 768 X 494-pixel resolution and 50-dB S/N in addition to selectable AGC and an automatic or fixed-shutter speed from 1/60 to 1/10,000 s. Using these features, systems integrators can better customize their CCD-camera modules for a range of image-processing applications outside the security market.

Special approachesRecognizing the limitations of AGC circuits, some companies have developed special approaches for automatic gain compensation. These include multiple-exposure methods in which two exposures are needed—long exposures for the dark scenes in the image and short exposures for the light scenes. In such designs, extra circuits are required to control and combine the two images to deliver broadcast transmission rates. While some security camera companies have adopted this technique, other companies such as C-Cam Technologies (Leuven, Belgium) and SMaL Camera Technologies (Cambridge, MA) are developing CMOS-based imaging modules that dramatically increase the dynamic range of the sensor using on-chip methods.C-Cam Technologies has developed a camera module based on the Ibis4b/c CMOS integrating active-pixel sensor from the Fillfactory (Mechelen, Belgium). This CCi4 camera needs only one frame to image scenes with a dynamic range of up to 100 dB. Unlike CCD sensors that collect photons to charge a capacitor, the CCi4 sensor is based around a fully charged capacitor that is discharged by the arrival of photons. If the capacitor is discharged faster than normally expected, a second discharge cycle is started at the pixel level. In this way, the sensor is capable of performing two exposure times in one frame, which results in a high-dynamic-range image.

FIGURE 3. Using frame-transfer CCDs in camera modules can increase fill factors to 100% and provide increased sensitivity and dynamic range compared to their interline-transfer CCD counterparts. The FTM1010 D/22/IG/M 1k x 1k digital camera module from Narragansett Imaging, for example, is designed for OEM applications.

SMaL Camera Technologies' cameras and image sensors are powered by the company's proprietary Autobrite technology, a CMOS sensor-based platform, to image scenes with widely varying light levels. By extending the dynamic range of a scene up to 500 times higher than conventional cameras, this technology can capture images regardless of extreme variations of brightness within the same scene. According to Cliff Drowley, director of product engineering at SMaL Camera Technologies, the sensor's proprietary technology uses different gates somewhat like shift registers to control the saturation voltage at each pixel in the device. In this way, the dynamic range can be changed from a linear 60-dB response to a 120-dB nonlinear response (see Fig. 2).

SMaL has also found great interest in its camera modules from automotive vendors seeking to develop intelligent driver-assistance systems. SMaL offers a development platform that allows vendors to test the performance characteristics of its systems in conjunction with its camera, and early results from several vendors have shown that the SMaL wide-dynamic-range imagers enhance the performance of the intelligent systems. The platform has a programmable interface that displays or transfers as S-Video, NTSC, or FireWire format.

Minolta (Ramsey, NJ) and ROHM (San Diego, CA) have also codeveloped a logarithmic converting CMOS log sensor with a dynamic range 1000 times larger than that of conventional CCDs. This is achieved by attaching a logarithmic converting circuit to each picture element of the sensor; these imagers are expected to first appear in consumer products such as video cameras, where the sensor will be used as a high-dynamic-range viewfinder.

Fill factorsMost standard CCD-board-level cameras also use broadcast-format CCDs to capture images. In many designs, interline-transfer devices are used. These devices use a nonsensitive light area in which the exposed charge is transferred after each image is exposed. As a result, such interline-transfer devices feature exposures as fast as 100,000 s. For example, the 20D489 color camera module from Videology Imaging Solutions (Greenville, RI) uses a 1/3-in. interline-transfer CCD that provides a shutter speed from 1/50 to less than 1/100,000 s.Despite the high shutter speed of these interline CCD-based camera modules, the gap between each pixel results in a nonlight-sensitive area that reduces the fill factor of such devices when compared to frame-transfer devices. This reduced fill factor decreases both the signal-to-noise ratio and the quantum efficiency at each charge site.

Frame-transfer CCDs feature a 100% fill factor, which provides greater sensitivity and dynamic range than their interline-transfer CCD counterparts. For example, the FTM1010 D/22/IG/M 1k X 1k digital camera module from Narragansett Imaging (Slatersville, RI) is designed for OEM applications (see Fig. 3). Consisting of a sensor board containing a 1k X 1k frame-transfer image sensor, the board produces 10-bit, 1k X 1k images at 22 frames/s. Because the charge for each pixel has to be moved across the whole sensor to the nonsensitive area, the frame-transfer rate is limited when compared with interline-transfer devices. However, in high-resolution medical-imaging applications, the increased signal-to-noise ratio and fill factor obtained are workable trade-offs.

Machine-vision applicationsWhile many camera modules are embedded in low-cost security applications, others are finding use in machine-vision applications. Last year, for example, RVSI Northeast Robotics (Weare, NH) built a customized and automated high-speed vial reader using four STC-150/180 monochrome board cameras from Sensor Technologies America. To capture the analog RS-170 output from each of the four cameras, RVSI built a custom cable to interface to its Visionscape Express machine-vision system. During operation, the Visionscape 1304 PCI board digitizes each RS-170 analog signal and analyzes the images of the barcodes located on the base surfaces of the 24 vials captured in each of the four sectors of the image (see Vision Systems Design, August 2001, p. 7).Now, Symagery Microsystems (Ottawa, Ontario, Canada) has introduced a barcode and matrix-code reader based on the company's 1.3-Mpixel VCA-1281 imager (see Fig. 4). With a built-in lens, illumination and targeting mechanism, and a proprietary ASIC, the SX4000 image reader performs as an imaging module that decodes barcodes, linear and stacked matrix codes, and postal-specific barcodes.

For machine-vision, automotive, and security applications, low-cost CCD- and CMOS- based application-specific imaging modules are expected to dramatically reduce the cost of end-user applications. At the same time, new CMOS-based logarithmic imagers are projected to open new markets, especially in high-speed automated inspection and embedded automotive and medical applications.

Company InformationFillfactoryB-2800 Mechelen, Belgiumwww.Fillfactory.comMinolta Corp. USARamsey, NJ 07446www.minoltausa.comROHM LSI Systems Design CenterSan Diego, CA 92121www.rohmelectronics.comRVSI Northeast RoboticsWeare, NH 03281www.nerlite.com