AUTOMATED INSPECTION: Cameras capture coffee capsules

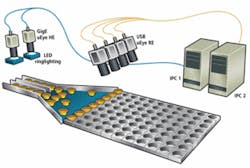

Optima Group Consumer (Schwäbisch Hall, Germany; www.optima-packaging-group.de) is a leader in the manufacture of coffee capsule filling systems, supplying to major coffee producers worldwide. For a leading North Italian coffee roaster, Optima delivers packaging stations that incorporate machine-vision systems from Seidenader Automation (Markt Schwaben, Germany; www.seidenader.de). In these capsule filling systems, two uEye GigE and four uEye USB cameras from IDS Imaging Development Systems (Obersulm, Germany; www.ids-imaging.de) are used to check the capsules before filling and to ensure they are properly sealed after filling (see Fig. 1).

FIGURE 1. In its coffee capsule filling systems, Optima incorporates machine-vision systems from Seidenader Automation that use two GigE and four USB cameras to check the capsules before filling and to ensure they are properly sealed after filling.

To avoid waste, the empty plastic capsules are first checked for frayed edges and deformities before filling. Any capsules damaged in transport must be reliably detected and separated. To accomplish this, the system uses two IDS UI-5220-M VGA cameras with a GigE interface, which each monitor the capsules as they traverse a conveyor belt.

Together, both cameras can inspect up to 500 capsules per minute. After they are triggered by a light barrier, the cameras in turn control the incident light from an LED light and capture images of the capsules. As the industrial PC used for image processing is located relatively far away from the place of inspection, Seidenader Automation chose camera models with a GigE interface.

Within less than a tenth of a second, Halcon machine-vision software from MVTec Software (Munich, Germany; www.mvtec.com) is used to detect defective capsules and reject them from the conveyor belt using pneumatic actuators.

Specially designed metal holders then convey the capsules in rows of eight and feed them into the filling station. Depending on type of coffee, up to 10 g of coffee powder may be dispensed. After the correct amount of coffee is weighed it is pressed into the capsule. Filled capsules are then sealed to keep the aromatic coffee fresh. In addition to ensuring that the membrane seal is placed accurately and there are no creases at the edges, the system must also check whether the label is centered.

For these tasks, Seidenader Automation uses four IDS UI-1540RE-M USB monochrome cameras equipped with lockable cables and a protective lens tubes (see Fig. 2). Because these cameras meet the IP65/IP67 standard, protection class, no coffee dust from the filling station can enter the camera optics or electronics.

Each UI-1540RE-M camera is used for imaging two coffee capsules at a time. At throughput rates just above one second, captured images are once again processed using MVTec’s Halcon machine-vision library. As a result, a row of eight capsules is inspected in only 600 ms. Capsules with a defective seal are separated immediately, resulting in no scrap at the end of the line.