Portable and mobile reduces size, weight, and power

Portable and mobile reduces size, weight, and power

By David Wilson

ue to their burdensome weight, power, and size, current computer-aided tomography (CAT) scanners, which are used to generate detailed images of human organs, are generally stationary, fixed-location machines. In addition, they are designed specifically to work in a controlled hospital-room environment, where the temperature and humidity are carefully regulated. They also require large amounts of power. In fact, because these scanners need such high currents for operation, they cannot be connected to standard power outlets. Consequently, special power provisions must be implemented.

To overcome these drawbacks, designers at Analogic (Peabody, MA) have developed a lightweight CAT scanner that one person can operate and easily move among hospital rooms. What`s more, all the scanner components are compactly packaged. This novel scanner can also be plugged into standard electrical outlets around the world and can withstand a range of temperature and humidity conditions.

The mobile CAT scanner is currently marketed worldwide as the Philips Medical Systems Tomoscan M system. During operation, it produces quality images at only one-third the milliamperes required by conventional equipment and at lower effective radiation dosage to patients. As for performance requirements, the scanner runs from an 88 to 264 Vac single-phase supply, needs less than 2 kW peak power, or 0.6 kW in standby mode, and can function over a temperature range of 15C to 40C at a humidity of 30% to 85%.

Says Analogic chief executive officer Bernard Gordon, "In designing a scanner like this, only three things matter: size, weight, and power. If you can reduce all of them, you can bring down the cost of the system." The designers of the Tomoscan M system met all these goals.

System units

The scanner system contains several units that, aside from their size, are not radically different from their predecessors. For example, a scanning gantry is pivoted at each side of the system and turns in a vertical direction (see Fig. 1). Mounted in the center of the gantry, a disk unit houses the x-ray tubes and detectors and the high-voltage generator that powers the x-ray tubes.

Using a console unit, the CAT scanner operator enters data and commands to a Sun Microsystems (Palo Alto, CA) Sparc workstation that controls the overall system. The operator can view and manipulate the CAT images, which are generated by an Analogic array processor, on a 17-in. monitor, as well as display text information, such as a patient`s records.

A tabletop gurney is used to position the patient within the CAT scanner. It is moved longitudinally to transport the patient through the aperture of the scanning gantry and, therefore, through the x-ray beam. The tabletop can also be moved vertically to position the patient`s body in the center of the gantry aperture and to allow medical staff easy access to the patient.

Design innovations

Because CAT scanners use a similar set of building-block units, it is not intuitively obvious what is different about the Analogic design. For instance, in dealing with the power requirements, a typical CAT scanner consumes 20 to 100 kW of power. The Tomoscan designers recognized that a CAT scanner able to be powered by almost any common worldwide outlet calls for a maximum power limitation of 1.3 kW (see Fig. 2). "That requirement was considered impossible, but we made it," says Gordon.

Limited to that low power requirement, Analogic engineers set out to reduce the x-ray power required by the tubes to a fraction of what was previously considered mandatory. "Because we wanted the CAT scanner to work with an average power of 1300 W or less, we needed to develop a very-low-power x-ray system," says Gordon.

The first design goal was to reduce the size and the weight of the scanner. These factors, in turn, would radically affect the x-ray power requirements. "A fundamental law is that the flux (from an energy source) decreases as the square of the distance from the source. So we moved the x-ray sources much closer to the body than before," states Gordon. The design result achieved is that, compared with conventional devices, only a third of the power is needed to power the x-ray tubes.

Coupled with a more efficient detector design, the designers found that just 5 to 6 kW were needed for the new CAT scanner. However, these parameters still exceeded the power that could be drawn from ordinary wall outlets.

Consequently, the system designers turned to a means of storing energy in the accumulators, which were located in the rotating part of the machine. The accumulators, made up of four banks of 48-V battery groups, are used to store the electric power needed to drive the high-voltage generator. In turn, this generator powers the x-ray tube during a scanning session. Between patient scans, the accumulators can be recharged to the levels necessary to perform another scan; however, the accumulators retain the capacity to perform 100 scans without recharging.

"We determined how many x-ray photons were received by our improved detector set-up, and then translated the number of photons back into the number of joules of energy needed to power the x-ray tubes to produce a quality image. We concluded that a fairly modest amount of electrical storage capacity was required to run a single patient scan," notes Gordon. It is a high-precision unit that runs off dc instead of ac power, he adds. Moreover, because the generator must operate over the entire range of battery accumulator variations, the power supply is highly regulated and accurate to a few hundredths of one percent.

Analogic claims that it has gained significant expertise in the development of data -acquisition units for CAT scanners because it now builds about 85% of all such acquisition systems installed worldwide. In a CAT scanner, the least significant bit in a data word corresponds to around 500 electrons. Therefore, a low-noise, highly stable multichannel data-acquisition system is compulsory.

"In some machines that we have designed recently, we use a custom 20-bit ds "analog-to-digital converter, one for each data-acquisition channel," explains Gordon. "On this portable CAT scanner, however, an older approach was actually taken. We used a multipole integrating filter whose output is multiplexed into a single 20-bit A/D converter," he adds. The older approach requires less power.

Highly efficient detectors are also used in the new design. They collect about 99% of the available photons, and Gordon says that this value compares well with traditional approaches. Gas detectors, for example, would be only 40% to 50% efficient.

Each new detector consists of a scintillator bonded onto a high-precision low-leakage diode. Upon receiving an x-ray, the scintillator converts the x-ray energy into optical energy. The optical energy is then coupled to a diode that emits a low current. In fact, the full-scale current, which occurs when no patient is present in the system and all x-rays are being detected, is only on the order of 100 nA. Therefore, shielding such a system from noise presents a major system design challenge.

Furthermore, because the detectors are temperature sensitive, they had to be built into an isothermal shield, so that the temperature of every detector can be determined within 1/50C. Armed with this detector design, the scanning system can automatically compensate for signal reading deviations due to temperature changes.

After acquisition, the data must be brought out from the rotating portion of the system. Because the scanning gantry is rotating continuously, the data obviously cannot be brought out through a wire. The derived design solution involves data telemetry via a capacitive-coupled RF data link between an antenna mounted inside the rotating part of the gantry and the stationary part of the gantry.

However, because the CAT scanner had to function correctly in the presence of mobile phones, television stations, and other spurious RF interference that might produce crosstalk, the data link must be highly reliable. To address that challenge, the Analogic designers use both FM modulation of the transmitted signal and an error-detection and correction scheme to minimize data errors. The resulting data transmission scheme allows only one bit to drop out of every 1012 bits.

After data collection, the scanned image must be reconstructed from the data before being delivered to the Sun Sparc workstation for display. Because on the order of a billion calculations are needed to compute a single scanned image, the designers used an Analogic AP 85 array processor that runs a mathematical back-projection software process to create the image. Once the array processor has computed the image, the result is sent over an Ethernet communications link to the Sun workstation for display.

Because of the numerous innovations in the portable CAT scanning system, Analogic was requested to supply a fixed-location scanning system that would reduce costs for medical facilities that do not require scanner mobility. Therefore, the company supplies two versions of its Tomoscan system. In the EG system, the fixed CAT scanner comes with a fixed tabletop. In the M system, as described, the tabletop is a separate, movable component. When docked to the scanning gantry, the tabletop becomes an integral part of the system under the control of the operator`s console.

The numerous CAT scanner design innovations, many of which are patented, have been incorporated into another new scanning system that Analogic has developed for its OEM partner Philips Medical Systems.

DAVID WILSON is a science writer in London, England.

cut -5

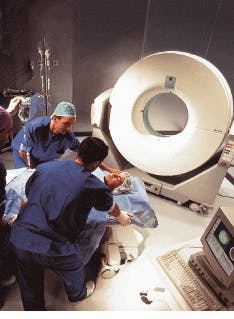

Medical attendants prepare patient for x-ray analysis by the Tomoscan scanning system designed by Analogic. This portable, mobile CAT scanning system incorporates several design innovations to achieve a smaller and lighter device that saves power and costs.

FIGURE 1. Within the fundamental building blocks of the Analogic CAT scanner system, the x-ray tubes are located on the scanning gantry along with the high-voltage power supply, x-ray detectors, and data-conversion system. The Analogic AP 85 array processor and the Sun Microsystems` Sparc workstation are used to create and display the scanned image, respectively.

FIGURE 2. Unlike other CAT scanner systems, the Philips Medical Systems Tomoscan scanner does not require enormous amounts of continuous electric power. It can be plugged into standard electrical outlets worldwide.

CAT scan basics

Computer-aided tomography (CAT) scanners have been designed and developed for more than 25 years. During that time, the fundamental principles that govern their design have remained constant. Inside the CAT scanner, x-ray tubes, powered by a high-voltage power supply, produce x-ray beams that travel through a collimator, which in turn, shape the beams before directing them through a patient`s body.

After passing through the patient`s body, multiple detectors pick up the x-rays and pass the signals to a data-acquisition system. After digital conversion, the data are downloaded via a communications link to a special-purpose workstation computer, where the image of the patient`s body scan is reconstructed. Completing the scanning system is a display subsystem at which the operator controls the machine, examines the data, and records the results.

D. W.

Company Information

Analogic

Peabody, MA 01960

(978) 977-3000

Fax: (978) 977-6814

Web: www.analogic.com

Philips Medical Systems

Elmsford, NY 10503

(914) 345-8000

Fax: (914) 345-8190