Automated Inspection System Detects Defects in Carbon Fibers

Inspecting carbon fibers during production typically is done manually—an inefficient and imprecise process because the fibers are tiny, making them difficult to see, and the manufacturing process is complex and continuous, making inline manual inspection impractical.

That is why the Fraunhofer Institute for Casting, Composite and Processing Technology IGCV (Augsburg, Germany; www.igcv.fraunhofer.de) developed an automated inspection process in 2016, called OptiMa II, which it recently updated and released as OptiMa III. SGL Carbon GmbH (Wiesbaden, Germany; www.sglcarbon.com/en/) was the project coordinator of the project, and it enabled Fraunhofer IGCV to implement the inspection system on its production line. In addition to carbon fibers, SGL Carbon produces carbon-based solutions from specialty graphite, carbon fibers, and composites.

Carbon fibers are small. A single filament has a diameter of 7-12 micrometers, which is about 0.0003 of an inch, according to Steffen Geinitz and Andreas Margraf, managers at Fraunhofer IGCV involved in the project. (They jointly answered written questions from Vision Systems Design about the project.)

Several thousand of the fibers are incorporated into what is known as a roving, and several rovings are produced at the same time during a three-stage continuous manufacturing process in which fibers go from glossy white in color to dull black. After the rovings are produced, resins are added to them, and then they are cured and put into the correct shape.

The fibers are used in carbon reinforced plastics, which can be found in aircraft, automobiles, sports equipment or in medical applications such as prostheses, according to Fraunhofer IGCV.

Manual inspection of the rovings has typically involved detecting fuzzballs on the production line through human observation or weighing broken filaments to detect loose ones. In addition, the performance of an individual batch of fibers can be tested mechanically, but this typically occurs after the manufacturing process is finished.

How the Automated System Works

OptiMa, in contrast, inspects rovings as they are produced.

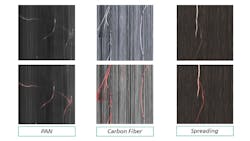

The system detects protruding filaments, lint, and similar foreign bodies and distinguishes the types of defects in carbon fiber, enabling carbon fiber production processes to be continuously and automatically monitored throughout manufacturing. This continuum includes not only the production process for aerospace-grade carbon fiber but also PAN spinning, which is an upstream process in which carbon fiber is obtained from polyacrylonitrile. OptiMa also can be used for inspection during a process known as spreading in which a continuous, flat fiber web is formed from several rovings.

For the first step in the inspection process, images are taken with an allPIXA wave color line scan camera with a CMOS sensor from Chromasens GmbH (Constance, Germany; https://chromasens.de/en), which is capable of capturing image data at a rate of up to 1 Gbps. The camera produces color resolution up to 15360 pixels x 4 lines with 5.6 μm x 5.6 μm pixel size and line scan lengths up to 15 k x 4 lines.

Data is then transmitted to an on-board FPGA using a frame grabber, microEnable 5 VD8-PoCL ironman, from Basler AG (Ahrensburg; Germany; www.baslerweb.com). The goal is “to isolate the rovings and single anomalies in real-time. A program then reads the images from the frame grabber channels and stores them in a local exchange directory. Subsequently, a PC-based application scans the exchange directory for updates and processes any incoming images. If a new image arrives, it is processed by a deep learning model and scanned for anomaly features. The resulting mathematical descriptions of single defects are written to a local database and passed to a web-based application to update and display the process status,” according to Geinitz and Margraf.

The system is built using Basler AG’s Visual Applets, commercial communication and imaging software from Chromasens, and HALCON from MVTec Software GmbH (Munich, Germany; www.mvtec.com).

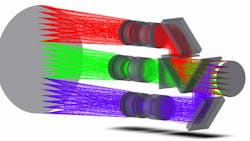

To expand the sensor's measurement width, Fraunhofer IGCV designed an optical software solution that triples the camera's field of view (FoV) while keeping the data volume the same. The system was designed primarily for large-format line sensors up to 85 mm. However, it is transferable to smaller sensors or area sensors. To integrate the system quickly and easily into the process, it also provides autofocus, which compensates for process-related fluctuations in the object plane.

Fraunhofer IGCV also deployed a Corona II illumination system from Chromasens to ensure high-contrast images, despite the deep black color of the fiber, which absorbs a lot of light. “As the speed of the production process was predefined by the carbon fiber manufacturing process, only an increase in brightness of the illumination allowed us to meet the requirements,” Geinitz and Margraf write.

Benefits for Manufacturers

For manufacturers of carbon fiber, getting inspection information directly from the fibers while they are in production is the main benefit of the system, Geinitz and Margraf say. The types of anomalies and defect types that are now visible through the system include a single filament that escapes a roving, debris down to a size of several micrometers, and fuzzballs consisting of only a few fibers.

“All in all, various anomalies can be detected and analyzed in real-time. The deeper process understanding, and constant, high-resolution image-based monitoring enables companies to increase their production efficiency in the long run by unveiling even the slightest configuration mismatch,” Geinitz and Margraf write.

About the Author

Linda Wilson

Editor in Chief

Linda Wilson joined the team at Vision Systems Design in 2022. She has more than 25 years of experience in B2B publishing and has written for numerous publications, including Modern Healthcare, InformationWeek, Computerworld, Health Data Management, and many others. Before joining VSD, she was the senior editor at Medical Laboratory Observer, a sister publication to VSD.