System accurately inspects printed-circuit boards

Maintaining precision and throughput in printed-circuit-board (PCB) assembly is a challenging process, especially when placing small components on high-density boards. Because defects can occur at any production step, such as solder-paste deposition, chip placement, fine pitch components placement, and reflow soldering, an end-of-line inspection occurs too late in the process to be cost-effective. The solution is automated optical inspection (AOI)—a process that permits an assembly line to operate at high production rates while inspecting paste deposits, mounted components, and solder joints.

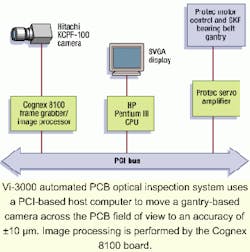

At the Vision Show East, held in Boston, MA, last month, Vision Inspection Technology (VIT; Haverhill, MA) demonstrated the Vi-3000 system, which is capable of inspecting PCBs at speeds to 150,000 components per hour. "In the design of the system," says Larry Sirolis, a VIT sales engineer, "images of each individual PCB are digitized using the KCPF-100, a 1300 x 1030 x 10-bit-resolution camera from Hitachi Denshi America (Woodbury, NY). "This camera is moved across each field of view on the PCB to obtain the required accuracy needed to perform AOI inspection," he adds.

Motion control is performed by transferring positional data from the image-processing system to a PCI-based servo-motor controller from PraTEC GmbH (Rohr, Germany). In turn, this controller directs a precision gantry-based motor controller system from SKF USA (Norristown, PA). This system provides an accuracy of ±10 µm and a repeatability of ±5 µm at speeds to 80 in./s.

After images are digitized by a PCI-based 8110 Series image-processing board from Cognex Corp. (Natick, MA), the Vi3000 system checks for the presence of components, confirms their values and polarity, and ensures placement accuracy using an advanced inspection technology called vectoral imaging. "Rather than inspect each part on the PCB against a typical image of how the part should ideally appear," says Sirois, "our proprietary software package combined with Cognex image-analysis tools was used to develop a database of synthetic images that are stored in the system library. These model images are then compared with the captured images to perform the AOI process," he says. According to Sirois, Cognex was, at the time the machine was developed, the only machine-vision vendor to provide such a part-modeling tool.

A user interface developed by VIT using Microsoft's C++ development system incorporated with statistical process-control software from Lighthouse Systems Limited (Crawley, West Sussex, England) provides users with process-control charts showing data and analysis of manufacturing trends.