Pork Process

Andrew Wilson, Editor

To increase the efficiency and effectiveness of meat production, food processing and packaging companies are looking to automate every aspect of production. Although the packaging of finished food products is a relatively simple task, automating the processing of slaughtering and then butchering the animals is more complex.

In many US-based slaughterhouses, for example, thousands of animals a day must be processed, a procedure that involves electrocution, exsanguination, scalding, dehairing, debunging, and evisceration stations. Within the cleanrooms of these slaughterhouses, carcasses are debunged, a process that involves cutting around the rectum of the animal with a knife and then removing the detached rectum.

“In many of these abattoirs,” says Markus Tarin, president and CEO of MoviMED (Irvine, CA, USA; www.movimed.com), “this process is performed manually and is both a complex and rather unenviable task!”

MoviMED has developed a vision system that uses a 3-D vision-guided robot—which the company claims to be one of the first systems of its kind in the United States—to automate this task. Installed in one of the largest pork production facilities in the country, the system uses a high-speed, laser-based 3-D camera from Automation Technology (Bad Oldesloe, Germany; www.automationtechnology.de) that is mounted to an M-710i industrial robot from Fanuc Robotics (Rochester Hills, MI, USA; www.fanucrobotics.com).

“To perform the task of debunging,” says Tarin, “the robot arm is also equipped with a pneumatic vacuum saw.” After dehairing, each of the pig carcasses is hung upside down by both legs and moved along a conveyor to the debunging station.

Because the debunging process must take place as the carcass is moving, robot motion is first synchronized with the speed of the conveyor. As each carcass reaches a specific point along the conveyor, the Automation Technology 3-D laser scanner is used to scan over the rear of the meat and point cloud data of the buttocks and rectum captured into a host PC (see Fig. 1).

“One of the challenges in developing the system,” explains Tarin, “was to avoid imaging the tail of the pig as the rear of the animal was scanned.” To overcome this, Tarin and his colleagues ensured the laser scanner imaged the meat at a 45° angle rather than directly from above. In this way, imaging the tail was avoided.

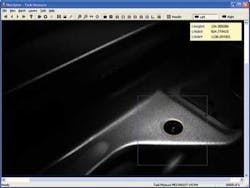

Once point cloud data are captured into the host PC, they must be analyzed and the location of the rectum clearly delineated to perform the debunging process. Since every carcass varies, the system must accommodate different buttock shapes, whether any hemorrhoids are present, and specular reflections that may be due to remaining water from the dehairing process (see Fig. 2).

FIGURE 2. Once point cloud data are captured into the host PC, they must be analyzed and the location of the rectum clearly delineated to perform the debunging process. Once this is determined, x-y-z coordinates are transferred to a robotic saw that performs the correct incision and extracts the rectum from the carcass.

MoviMED developed a variety of proprietary 3-D image-processing algorithms to deal with the inherent difficulties of scanning organic matter, including 3-D spatial calibration templates to mimic depth of field required to scan all size variations of hogs.

“By determining a number of known anatomical features that exist in this database,” says Tarin, “the system can predict the precise area of the rectum to within 98% accuracy.”

Once this area is determined, its x-y-z coordinates are transferred to the M-710i robot controller. The robot then moves the saw into place, performs the correct incision, and extracts the rectum from the carcass using the vacuum saw.

In operation, the system is capable of performing this operation at a rate of approximately 500 carcasses per hour or 12,000 carcasses per day. After this process is complete, each carcass is further butchered into smaller portions and packed for shipping.