Hyperspectral imaging continues industrial growth

Peter Stiefenhöfer

Used for capturing images beyond the visible wavelengths, hyperspectral imaging (HSI) technology has become increasingly popular in industrial applications in recent years.

With hyperspectral imaging, spectroscopic analysis of objects can be accomplished to determine organic or inorganic impurities—not only on the surface—but also partly inside inspected materials. Hyperspectral imaging involves narrow, usually contiguous spectral bands, involving possibly hundreds or thousands of spectra. Such systems often utilize a spectrograph that splits the light reflected from the object into its spectrum and reproduce it on the camera sensor.

A hyperspectral imaging system assembles its resulting images into a 3D hyperspectral data cube that can contain large amounts of data. A data cube contains for each wavelength a calibrated spectral reflectance image, so that for any image pixel an entire spectral reflectance curve is provided (http://bit.ly/VSD-HSIDC). The result is what Austrian hyperspectral imaging company Perception Park calls a chemical fingerprint of the object under consideration, which enables the analyzed material properties to be precisely determined.

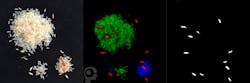

With the help of special evaluation software, each identified chemical component can then be flagged with its own color in the images taken in order to visualize the exisiting substances in a simple way for the user. This technology is called chemical color imaging (CCI).

Diverse applications

Hyperspectral imaging technologies can be deployed in a variety of industrial application areas and in certain cases offers solutions for tasks where conventional image processing systems fail, explains Markus Burgstaller, Managing Director or Perception Park.

One such example is in the classification of of substances that have no visual differences, but are not chemically identical.

“Plastics of various compositions can look very similar and can therefore hardly be classified by conventional image processing,” he says. “On the other hand, HSI systems are able to analyze chemical properties and therefore recognize materials very reliably. With this technology, the concentration and distribution of ingredients can largely be recorded in real time.”

Some substances are not transparent to visible light, but can be penetrated by infrared light. This makes it possible to check the chemical composition of packaged content even through its packaging. Applications in which this property comes into play include pharmaceutical and food industries, but also in numerous other industrial segments, says Burgstaller.

Fault detection in the pharmaceutical industry

As in many other areas, production speeds in the pharmaceutical industry are increasing rapidly worldwide. To reduce the risk of product recalls and to protect consumers from contaminated drugs, particularly strict safety regulations apply in this industry. Image processing systems have therefore been state of the art in the manufacturing processes of pharmaceutical products for some time to evaluate by shape, size, or weight. However, the use of hyperspectral imaging and CCI systems can further optimize the monitoring of pharmaceutical production processes, as pharmaceuticals can be fully examined by molecular properties.

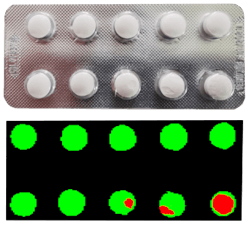

A typical application of hyperspectral imaging systems in the pharmaceutical industry is the checking of tablets for the correct coating. Certain medications release the active ingredients after its administration over a longer period of time or to a specific target in the body. For such medications to work properly, sustained release is necessary. If the coating is damaged or missing completely, the medication gets into the body faster than desired and fails to deliver its long-term effect.

With a combination of HSI and CCI technology, the quality of such medications can be reliably controlled, explains Markus Burgstaller.

“With a hyperspectral camera working in the near-infrared range and the use of chemical color imaging technology with our software suite Perception STUDIO, we were able to clearly demonstrate that previously artificially generated coating defects can be recognized with 100% certainty and also in real time in high-speed production,“ he says. ”This quality check is possible even through blister packs, provided the blister material is not made of aluminum, which would reflect the NIR radiation.“

Hyperspectral imaging can also be used to reliably check whether the correct number of tablets are packed in blisters, whether they are undamaged and free from any contamination, whether the correct ingredients are contained in drug capsules, or whether they are completely sealed.

"Hyperspectral imaging offers numerous application options in the pharmaceutical sector and thus increases safety for patients and manufacturers,“ he says.

More security in food production

Similar guidelines to those in the pharmaceutical industry apply in the production of food. In order to exclude health risks to consumers, no contamination must remain undetected. Food must also contain only the intended ingredients that are defined in the product descriptions for the consumer.

Hyperspectral imaging and CCI also offer numerous application options for this industry. These techniques make it easier to find any contamination in food and identify unwanted objects such as stones or earth when sorting potatoes, carrots, or other vegetables, as well as shell parts or other substances in the production of nuts, even in high-speed production lines. If food is stored for too long, maggots can also nest or fresh fruit can start to rot, according to Burgstaller.

“In food production, the task very often not only means to detect any contamination, but also to identify rotten, immature, or pest or mold infected goods,“ he says. ”These and many other quality defects can be safely ruled out by the use of hyperspectral imaging systems."

Industrially-manufactured food such as sausage and cheese are usually offered for sale in a shrink-wrap form. Similar to the pharmaceutical industry, HSI systems also allow quality checks through the packaging in many cases. A special task here is the inspection of heat-sealed joints, which are supposed to guarantee tight packaging of the food. Even the smallest contamination or damage to these sealed joints can lead to leaky packaging and spoilage of the goods before the calculated best before date. Unsellable products or expensive product recalls would then be possible consequences for manufacturers in this area, which can be avoided in many cases by using hyperspectral imaging.

Additional applications

Beyond those already mentioned, hyperspectral imaging can be used to check the quality of products such as sawn timber, wood-based materials, wood chips and paper and paper products in wood processing. The technology can also detect features invisible to the human eye as well as damp spots in wood, resin pockets, or knotholes.

"For high-quality wood products, the reliable detection of such defects is an imperative," emphasizes Burgstaller. "Hyperspectral imaging systems offer a powerful tool for this industry to avoid undesirable quality defects in time."

Additionally, hyperspectral imaging can help in plastics sorting applications, says Burgstaller.

"A distinction e.g. between polypropylene and polyethylene or other materials that look very similar at first glance, hyperspectral imaging makes it easy to do so,“ he says. "With our Perception STUDIO, appropriate systems can be developed even by people who have little or no experience with the subject of spectroscopy.“

He continues, "The technical possibilities for a significant expansion of the recycling quotas for plastics are therefore already available and for environmental reasons should be used substantially.“

Experience hyperspectral technology live

On May 27 and 28, 2020, representatives of the manufacturing industry will have the opportunity to learn about the latest trends in hyperspectral imaging during the fourth conference on Hyperspectral Imaging in Industry (chii) in Graz, Austria. The focus of this international industry meeting is the use and application of hyperspectral systems, which are presented in numerous short lectures by leading technology providers and in the context of an exhibition. Matchmaking meetings are also planned to answer individual questions. Details on the program and registration for chii 2020 can be found at www.chii2020.com.

- Peter Stiefenhöfer is the owner of PS Marcom Services