Digital pixel enabled infrared imaging boosts camera speed and performance

Despite compact design and low power consumption benefits, early analog infrared image sensors had limitations in frame rates due to analog video bandwidth constraints. Digital and digital-pixel-enabled infrared sensors, however, support higher frame rates and ultimately help ease system integration.

Infrared image sensors consist of a detector and a readout integrated circuit (ROIC), where the detector interfaces to the ROIC by means of indium bumps deposited on both the detector and ROIC. The two press together, creating a robust mechanical and electrical interface. Early ROICs were exclusively analog and implemented the entire ROIC signal chain using analog circuits only, including output signals.

With digital readout integrated circuits (DROIC), a digital output provides benefits over ROICs, including speed and the simplification of interfacing to other ICs. To facilitate digital output, analog-to-digital converters (ADCs) are introduced into the circuit design. Additional digital technology benefits include the simplification of the command and control architecture and a higher level of functionality to the readout IC. In terms of production volume quantity, the DROIC is currently the workhorse of the infrared imaging sensing industry and has been since the 2000’s.

Related: Choosing a camera for infrared imaging

The next wave in readout IC technology enables yet another leap forward in performance however, as the digital pixel readout IC (DPROIC) pushes the envelope further by integrating an ADC into every pixel. Today’s DPROICs will have pixel widths of around 12 µm and an array size of approximately 1 MPixel. The DPROIC will also be expected to support dual-band imaging, or the ability to operate with two types of detectors, like MWIR and LWIR, simultaneously.

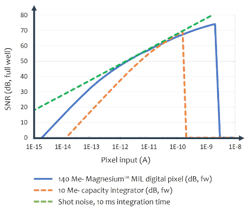

Digital pixel sensors disassociate well capacity from noise floor, enabling reduced noise and increased sensitivity even for very large well capacities. The chart here plots signal-to-noise ratio (SNR) against pixel input current for a large well capacity DPROIC such as the ‘Magnesium MIL’ DPROIC, compared to a typical smaller well size, non-digital pixel DROIC. It also highlights the enhanced sensitivity for low signals and greatly increases the maximum well capacity for large signals with long integration times.

Additionally, the chart shows shot noise, which generates from photons collecting over a given integration time (in this case, 10 ms). As the amount of shot noise present depends on signal size, smaller signals become more problematic. Shot noise is unfortunately a phenomenon that can’t be designed around—a perfectly-designed chip will be SNR limited by shot noise. The chart also demonstrates that the performance of the DPROIC tracks the shot noise curve more closely over a much wider range than the comparison DROIC.

The availability of DPROICs brings excitement to developers of infrared imagers, as the large well capacity capability and extended dynamic range of the DPROIC allows infrared imaging systems to get closer to operating at their theoretical maximum performance. Specifically, DPROICs can enhance high frequency contrast, which can make a significant improvement to the range of the infrared camera.

Related: Time of Flight sensors target high-speed 3D machine vision tasks

When coupled with suitable high-operating temperature detectors, enhanced gain represents another potential benefit to infrared system developers, as this offers the same or better level of performance as conventional DROICs, but at a higher operating temperature. Doing so relaxes the cooling requirements of the system and allows simplification of the cryogenic subsystem. Using a smaller Dewar-based cryogenic cooling system could potentially save significant size, weight, power consumption and cost.

The DPROIC’s wide dynamic range capability enables the observation of thermally subtle targets in the presence of high flux events that occur in the same scene, ensuring that the widest range of contrast in targets can be resolved under the most challenging conditions. Put simply, it is possible to observe very cold targets and very hot targets clearly in the same scene. This wide dynamic range is particularly welcome for infrared cameras deployed on the battlefield where all threats may not be obvious, unlike a high-temperature missile traveling in a particular direction. – Ross Bannatyne, Director of Business Development, Senseeker (Santa Barbara, CA, USA; www.senseeker.com).