Smart cameras check crates, count bottles

Andrew Wilson, Editor, [email protected]

In Venezuela, products such as beer are packaged in glass bottles that are shipped to consumer outlets in plastic crates. After consumption, consumers return the bottles to the store where they are shipped back to the brewery for washing, refilling, and repackaging. One of the largest corporations in Venezuela, the Empresas Polar (Caracas, Venezuela; www.empresas-polar.com) Cervecerias Polar subsidiary, owns four brewing plants designed specifically for brewing and recycling these glass bottles.

Before bottles can be refilled and repackaged, each crate must be checked to ensure the correct number and types of bottles are present. Should bottles be missing from the crate, the brewery will incur a loss, and a higher inventory of bottles will be required. Should the number of bottles be overestimated, these inventories will be overestimated. In either case, inventory management will be inefficient, resulting in increased cost.

“Until now it is has been impossible for plant managers to keep track of the losses generated by the missing bottles,” says Joseph Christenson, president of PPT Vision (Eden Prairie, MN, USA; www.pptvision.com). Last year, however, Empresas Polar called upon Sanot-MVS (Caracas, Venezuela; www.sanot.com.ve) to build a system capable of automating this process. A PPT Vision system integrator, Sanot-MVS has installed more than 100 machine-vision systems in Venezuelan companies such as Empresas Polar and Pepsico.

“In the development of the system,” says Christenson, “Empresas Polar specified that the system must be capable of accurately counting the number of bottles in the crate, determining whether there were empty holes (where bottles are not present), and accounting for any foreign objects that may have been returned in the crate.”

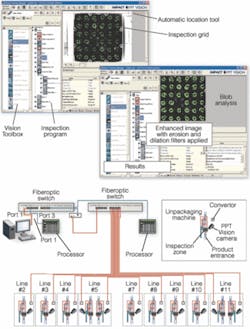

To detect the presence or absence of bottles within crates, Sanot-MVS uses PPT Vision’s T20 cameras to perform erosion and dilation operation (to reduce noise) and blob counting to check for the presence or absence of bottles (top). To automate nine inspection stations, the company interfaced all nine cameras using Ethernet to a fiberoptic switch that interfaces to multiple PLCs and to a host PC to monitor all nine cameras in real-time (bottom).

As crates of bottles are returned to the company, they are manually placed onto a conveyor line. “Because of the large number of crates being returned daily,” says Christenson, “each plant may have multiple lines. While the system installed by Sanot-MVS must inspect crates on nine lines, the company will install 39 such systems in Empresas Polar’s other plants in Caracas, Maracaibo, San Joaquin, and Barcelona.”

Before the bottles can be automatically removed from a crate, the crate must be inspected. To do this, Sanot-MVS mounted an Impact T20 smart camera from PPT in a housing with two lateral fluorescent lamps at a vision stage before each automatic unpacking station. With a standard 16-mm lens, the 640 × 480-pixel resolution of the camera captures images of the crates as they pass under the inspection station at 60 frames/s.

To check for presence or absence of bottles, Sanot-MVS engineers programmed the T20 smart camera using PPT Vision’s Inspection Builder software. “Because each T20 features an on-board PowerPC and Ethernet interface,” says Christenson, “it is possible to program machine-vision functions on a PC and download the program for execution.” And because many plant production managers want to remotely monitor images taken by the cameras, the subsampling function within Inspection Builder allows images to be resampled and transmitted over the Ethernet for remote system monitoring. “When multiple cameras are being used in multiple productions lines,” says Christenson, “this is a very important feature.”

After images are captured by the T20 camera, a morphological erosion and dilation operation is performed on each image to reduce the amount of specular reflection seen as noise (or white pixels) within each image. After this process, a blob count is performed to check for the presence or absence of bottles. “By defining the green areas as blobs,” says Christenson, “and then using a blob filter, the smart camera computes whether a bottle is present or absent from the crate. At the same time, if the blob counter detects a blob that is too large, then a possible contaminant may have been introduced into the crate.”

After building the machine-vision inspection software, Sanot-MVS understood that its customer would require an easy-to-use screen for its operators. The company used Control Panel Manager (CPM) software, also from PPT, to customize the user interface. “CPM is a human-machine interface that system developers can use as a GUI builder,” says Christenson. “As such, it can be implemented much faster than Microsoft Visual Basic or C++ interfaces, saving both time and money.”

Crates checked for the correct number of bottles and lack of any foreign objects then pass to the automatic unpacking station. Should a crate not be filled properly or possess contaminants, the T20 smart camera triggers a PLC from Rockwell Automation/Allen-Bradley (Milwaukee, WI, USA; www.ab.com) that, in turn, controls a reject mechanism that directs the crate to another conveyor where it can be manually inspected and properly filled.

To automate the inspection stations at Empresas Polar’s Caracas facility, Sanot-MVS interfaced all nine cameras using Ethernet to a fiberoptic switch. “This switch interfaces to both multiple PLCs on the production line and to a host PC that monitors all nine cameras in real time as crates pass under each of the inspection stations. “Better still,” says Christenson, “should any reprogramming of the cameras be required, this can be done remotely by addressing each of the camera’s IP addresses and downloading new machine-vision algorithms over Ethernet.”