Fast spatial light modulators speed optical-computing applications

Fast spatial light modulators speed optical-computing applications

By Richard Parker, Contributing Editor

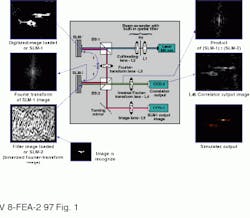

Optical correlators are widely used in medical, industrial, and agricultural inspection applications, primarily because of their high-speed pattern matching capabilities. By performing Fourier transforms at up to 300,000 frames per second, they can far exceed the rates of their electronic counterparts. Building optical correlators requires combining Fourier-transform lenses, optical beamsplitters, spatial light modulators (SLMs), a source of collimated light (usually a laser), and a charge-coupled-device (CCD) sensor to read the correlated output image (see Fig. 1).

To find a specific feature in an image, the image is first electronically written to an SLM. The image on the modulator is then reflected through a beamsplitter and passed through a lens, which produces a two-dimensional (2-D) Fourier transform of the image.

The resulting image is directed at a second SLM. This modulator is electrically programmed with a filter of the feature of interest being looked for in the image plane. In the case of a military application, for example, this might be the filter image of a jet aircraft. The output of the modulator is then passed through another lens, which performs a second Fourier transform. The output of this system is a 2-D correlation of the input image with the filter plane. Any pattern that corresponds to features existing in the input causes a bright light in the output image at the location of the pattern in the input scene. The output is typically read out by a CCD image sensor.

Light modulators

The fastest SLMs, according to Richard Stack, principal engineer with Sanders, a Lockheed Martin Company (Nashua, NH), are based upon gallium arsenide (GaAs) Fabry-Perot PIN diodes and provide switching times of 150 ns. The company`s 2-D arrays are currently operated in binary mode, whereas its one-dimensional arrays operate with six bits of gray scale per pixel.

Most SLMs are binary devices that use ferroelectric liquid crystals. These devices furnish switching times of 50 to 100 ms. Such speeds are more than an order of magnitude faster than analog SLMs that use twisted-nematic liquid crystals to provide gray-scale capability for more accurate video processing. However, because binary SLMs switch so quickly, they are just as useful for many applications formerly served by analog SLMs.

Even Texas Instruments (Dallas, TX), a supplier of digital micromirror devices (DMDs) for display applications, is offering DMDs as SLMs. The company is making DMD kits available to researchers in the form of evaluation kits for investigations in holography, confocal microscopy, optical computing and switching, and optical pattern recognition. Although some optics experts acknowledge that the individual micromirrors within the DMDs can switch faster than many SLMs (switching times are on the order of a few microseconds), overall throughput of optical correlators based on DMDs can be lower because the output of the correlator cannot be read at those rates.

Boulder Nonlinear Systems (Boulder, CO) has built analog 512 ¥ 512-pixel nematic SLMs that operate at 4000 frames/s. At that rate, the devices achieve a throughput of 8.4 Gbit/s. The company also makes SLMs that use ferroelectric liquid crystals. Both types are busy serving fingerprint-identification, PAP-smear, and cancer-detection applications. "Working prototypes are being used in holographic storage for computer mass-storage applications," explains Kipp Bauchert, an engineer at Boulder Nonlinear Systems.

DisplayTech (Longmont, CO) is another manufacturer of binary ferroelectric-liquid-crystal SLMs. It offers 256 ¥ 256-pixel SLMs that can operate at 3000 frames/s. A prototype 1024 ¥ 1024-pixel SLM, demonstrated last year, can handle a few thousand frames per second and is still under development. The company is trying to commercialize its SLMs into applications such as target acquisition, machine vision, and fingerprint matching.

Commercial applications

"We`re very interested in commercializing optical image processing," says Mike O`Callaghan, DisplayTech`s director of research. "We`re building an optical correlator module for the US Army that is the size of a business card," he adds, "under a Small Business Innovation Research contract for 2-D optical processing to demonstrate optical processing technology. It contains two SLMs, a laser diode, optics, and an ultrahigh-speed video detector. As far as I know, it`s the smallest correlator available," claims O`Callaghan.

The small size allows DisplayTech to offer correlator components that plug into a PC backplane. "Electronic engineers unfamiliar with optical electronics can become familiar with the benefits of optical computing. It`s irrelevant what`s inside the module; what is important is what it does, namely, optical image correlation," declares O`Callaghan, who sees multiple correlator modules eventually being used on a board.

At that point, according to O`Callaghan, optical computing`s throughput will outpace a PC`s ability to handle the data. He clarifies, "At 256 ¥ 256 pixels, SLMs can run at 5000 frames/s. A standard PC with a 32-bit bus can handle about 1 Gbit/s. So a 256 ¥ 256-pixel SLM running at 5000 frames/s already takes one-third of the PC bus bandwidth." The output of the correlator must then be examined with an expensive CCD camera that can handle 1000 to 2000 frames/s.

In many applications, therefore, electronic-based image correlation cannot compute Fourier transforms fast enough. In such cases, optical correlation must be used. Lockheed Martin (Denver, CO) already has its 256 ¥ 256-pixel binary ferroelectric-liquid-crystal modulators in use in a mammogram screening application performing optical correlation at an impressive rate of 80 GFLOPs.

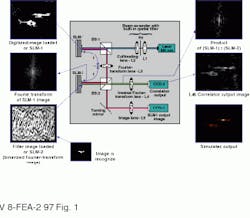

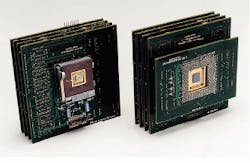

Engineers at Sanders, together with those at Analog/Digital Integrated Circuits (Orlando, FL), have also built a correlator that uses 128 ¥ 128-pixel SLMs to run at 300,000 frames/s. Based on an array of 128 ¥ 128 GaAs PIN diodes, the SLM is driven by a separate CMOS ASIC chip that is bump-bonded to the SLM chip. In operation, light falling on each PIN diode is read out in a parallel fashion one row at a time by the custom CMOS ASIC.

At present, each SLM in the correlator is being controlled by a custom EISA-based board. Future plans for a PCI based daughter card approach to control each SLM are in process. According to Sanders` Richard Stack, this design has now been updated to one using 256 ¥ 256-pixel SLMs that run at about 150,000 frames/s (see Fig. 2).

Integrated optics

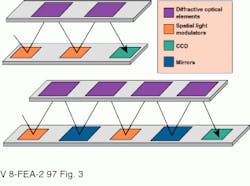

A key reason for the growth in the use of SLMs is the use of diffractive optics to make the lenses within a correlator. SLMs generally use refractive optics for lenses. In refractive optics, curved lenses must be hand-crafted and carefully aligned with respect to each another. Using diffractive optics, these lenses can be built as bumps on sheets of glass, mounted closer to each other, and aligned easily (see Fig. 3).

Because diffractive lenses can be built like integrated circuits (ICs), they can be mass-produced inexpensively. And with SLMs being made monolithically, entire correlators can be integrated on one or two ICs.

Performance disparity between PCs and optical correlators is one argument for an all-optical computer. But optical computers are not as programmable and as flexible as their digital counterparts. Nevertheless, optical computing components and subsystems are making inroads, because optical processing systems are more cost-effective at some tasks. Today, SLMs are used for correlation. Tomorrow, they may be used for optical logic functions.

FIGURE 1. Optical correlators find features within images by comparing the Fourier transforms of input images with a filtered input image of the feature of interest. The result is a correlated output image with a correlation peak. Operating at 150,000 frames/s, the 256 ¥ 256-pixel SLMs from Sanders are used mainly for military target recognition applications.

FIGURE 2. Engineers at Sanders and Analog/Digital Integrated Circuits have fabricated two correlators. The first (left) uses 128 ¥ 128-pixel SLMs to run at 300,000 frames/s. The second (right) uses 256 ¥ 256-pixel SLMs that run at 150,000 frames/s.

FIGURE 3. Planar approaches developed by DisplayTech for building optical correlators will shrink their size and increase their speeds and lifetimes. In the upper configuration, a CCD and two integrated-circuit SLMs are placed on a single substrate. Diffractive optical elements mounted in the element plane replace a correlator`s two Fourier lenses. In the lower approach, the functions of the Fourier-transform lenses are split among two diffractive optical elements (two elements for each Fourier-transform stage) and a mirror.