Vision ensures product and packaging quality

Smart camera and monitor inspect cosmetics tubes for proper filling and sealing.

by C. G. Masi,Contributing Editor

In an image-conscious industry such as cosmetics, product packaging is critical to market success. For example, a poorly crimped seal on a tube of hand cream can make the difference between success and failure in product sales.

When cosmetics-manufacturer Shiseido America sought to upgrade its East Windsor, NJ, packaging line, it turned to vision integrator Automated Design Solutions (ADS) to create an automated inspection system that would ensure that the right ingredient goes into the right tube and that would inspect the tubes to ensure that the crimp seals are aligned correctly with respect to the silk-screened label. The resulting system combined smart vision, a human-machine interface (HMI), and a custom control system to operate at production-line speed. The inspection system integrates with an existing packaging machine that fills and heat-seals product tubes.

COSMETIC PROBLEMS

“There were three similar products running on that particular filling machine that had very similar tube packages,” says ADS president Walter Kot. “The customer’s problem was that, because the tubes were very similar in color and lettering, the wrong tube would sometimes get mixed in with the correct tubes.” Potentially, a consumer could purchase a tube of skin cleanser and open it up to find it full of another product.

The first task was to find an identifying mark that would unambiguously tell the vision system if the tube it just filled with a certain product was, in fact, labeled for that product. If not, the tube should be removed from the production line. Each tube carries such an identifying mark, which is silk-screened onto it along with the rest of the label. Called an “eye mark,” this identifying mark is a small rectangle printed at the edge of a tube’s seal end (see Fig. 1).

FIGURE 1. Packaging system fills plastic squeeze tubes with product, heat-seals them, and inspects the package. The system is keyed to the eye mark, which appears as a red rectangle centered just under the seal at the tube’s top.

Eye marks differ for each product. For example, the eye mark for the cleansing skin foam is a solid rectangle. The eye mark for a different product has a white space near the bottom that breaks it into something that looks like an exclamation mark. A third product has a white space near the top.

“The eye-mark serves a number of different purposes,” Kot explains. “After the filler machine finishes filling each tube with product, the tube indexes to a rotary station where the tube is rotated. A sensor detects the eye mark and stops the rotation. This ensures that the tube is perfectly aligned with the silk-screened print on the tube. Several indexes along the machine “carousel” bring the tube to a crimping station where the end of the tube is heat-sealed.”

After several more indexes along the machine’s carousel, the tube is presented to the vision inspection system where the eye mark is inspected. A successful inspection of the eye mark allows the system to continue its normal production.

PRODUCTION FLOW

In the production flow for these products, the tubes come in from a handler, which sets them one by one into holders attached to a conveyor (see Fig. 2). The conveyor, or carousel, then moves the tubes past various stations. At this point the tubes have caps on them, but their ends are open. The handler sets each tube up with its cap down and the open end up to receive product. The handler pays no attention to where the silk screening is on the tube, so it may appear in any orientation.

FIGURE 2.Cognex In-Sight 4000 smart camera is mounted to view the heat seal at the top end of a vertically oriented tube. The camera’s position can be adjusted when the machine is set up for one of three similar products to ensure the best view. Illumination comes from a white LED line light mounted near the package.

The first station is the filler. A hopper above the filler carries a supply of a product such as cleansing skin foam. A dispenser forces a measured amount of foam into the open end of the tube, then signals the PLC running the packaging machine that it is ready for the next tube.

The next station orients the tube for sealing. When it reaches that station, the PLC turns on a motor that rotates that tube holder. As the tube rotates, a photoelectric sensor watches for the eye mark to come around. When it sees the eye mark, it sends a signal to the PLC to stop the motor when it reaches the correct position for the heat sealer. The PLC then indexes the carousel to the heat sealer, which then seals the tube and tells the PLC when that job is done.

At the next station, the camera looks at the eye mark to ensure that it matches the product the line is set up to fill. It also checks to make sure the eye mark lines up properly relative to the heat seal. It can inspect for cosmetic defects, such as blurred or smeared lettering embossed on the heat seal. The camera then tells the PLC if the tube is ready to ship. Finally, the PLC triggers the carousel to index to the final position where the handler sends the tube to be shipped.

Should the camera find an incorrect eye mark, the HMI controls automatically stop the filler machine and provide a visual and audible alarm to alert a human operator. The HMI then displays the inspection image and stores it along with the previous 100 failed images for review.

SYSTEM ARCHITECTURE

Since all of the stations work with tubes on the same conveyor line, it is important that they all finish their tasks before the line indexes. If the line runs slowly enough to ensure that each station has enough time to complete its task in the worst case, significant production time can be wasted. If it runs faster, however, some tasks are not completed and yield drops. The result is usually a trade-off between production speed and yield, yet Shiseido wanted 100% yield with no wasted time.

The packaging machine runs under supervision of a PLC that communicates asynchronously with all of the stations. As each station completes its task, it signals the PLC. Only when the PLC has “task-completed” signals from all stations does it index the conveyor. If there is no tube in a holder that should carry a tube-which could happen if a tube falls out or an operator removes a tube-then the photoelectric eye-mark sensor will not find an eye mark and the station stops the rotation, notes to the PLC that there was no tube in the holder, and waits for the next cycle to come around. This architecture works best when each of the stations is relatively autonomous, especially the inspection station, which has the most complex task to perform.

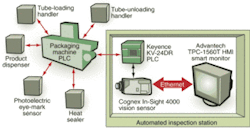

The inspection station consists of a Cognex In-Sight 4000 vision sensor, which carries its own on-board image-processing intelligence and software vision tools, a Keyence KV-24DR PLC, and an Advantech TPC-1560T touch-panel computer with Crusoe 5400 processor and 15-in. TFT LCD display (see Fig. 3).

Using a smart camera such as the In-Sight 4000 simplifies the layout and interconnection because the camera has both digital I/O to exchange logic signals with the PLC and an Ethernet port for complex message exchanges with the TPC-1560T smart monitor. For example, it uses Ethernet to upload images to the HMI.

“Ethernet provides communication to allow capabilities such as programming and data transfer,” Kot points out. “In this instance, our interface program can communicate with the camera to retrieve and display inspection images, change system variables stored within the camera, and change vision tools that the camera uses without needing to go into the camera’s software to do it. That gives the customer a lot of flexibility.”

FIGURE 4.Advantech monitorwith on-board intelligence provides the system¿s HMI, which runs on ADS Vision, proprietarysoftware developed by Automated Design Solutions using National Instruments LabVIEW.

features, advantages, benefits

Thomas Halligan, executive director of operations at Shiseido America, says, “This error-proofing system represents an important part of our investment in quality. As a fully automated facility, we need to prevent commingling of physically similar packages with different printing. This is critical to satisfy regulatory requirements that dictate many aspects of the labeling, such as listing of ingredients, and maintaining our Good Manufacturing Practices certifications for industrial quality, operational quality, and product quality under the US Food and Drug Administration’s CFR 21 rules.

Our working relationship with Automated Design Solutions made it possible for the company to thoroughly understand our needs and produce a system that worked right the first time. Since we installed it, it has proven 100% successful.”