What is machine vision?

Machine vision is often thought to be one in the same with computer vision, however these are really two different terms for overlapping technologies. Computer vision generally refers to the automatic extraction of information from digital image data with an emphasis on the image analysis function, across a wide range of theoretical and practical applications.

In contrast, machine vision traditionally refers to the use of computer vision in an industrial or practical application or process where it is necessary to execute a certain function or outcome based on the image analysis done by the vision system. The machine vision system uses software to identify pre-programmed features and is frequently used to trigger a variety of set “actions” based on the findings.

Today’s off-the-shelf machine vision components have emerged from research in numerous fields including optics, mathematics, physics, computer design, and electrical and mechanical engineering. In his book “Understanding and Applying Machine Vision,” Nello Zuech points out that the concepts for machine vision are evident as far back as the 1930s, with a company called Electronic Sorting Machines (then located in New Jersey) offering food sorters based on the use of specific filters and photomultiplier detectors.

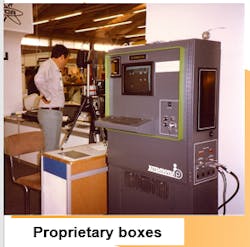

The widespread use of machine vision in industry arose in the 1980s with machine vision systems that were essentially purpose-built systems, or proprietary boxes such as the photo above, which was taken from the Wikipedia entry on machine vision and shows an early 1983 tradeshow exhibit of a system by Automatics.

Later in the technology evolution, embedded boards were developed. These generally used RISC (Reduced Instruction Set Computing) processors and custom ASICs (Application Specific Integrated Circuit) to deliver pipelined processing power.

In the 1990s, PC-based machine vision systems were commonly developed. Then, after the turn of the century, smart cameras and vision sensors were being developed. These systems typically featured on-board image acquisition, processing, and digital I/O, as well as offering serial and Ethernet TCP/IP compatibility. These systems generally included the company's proprietary software.

Today, OEM vision systems such as the Cognex AE2 Advantage image engine provide vision and code reading technology for many cost, size, and power-constrained applications found in clinical diagnostics, kiosk, and medical device applications.

Advances in machine vision technology have led to the development of vision sensors, smart cameras, vision controllers, or embedded industrial PC platforms as alternative choices for the machine vision system designer.

Application-specific machine vision systems are another, potential choice. Choosing the right machine vision platform generally depends on the requirements of the application. The key differentiators include development environment, capability, architecture, and cost.

The idea that computer vision would transition from a niche research technology to a mainstream technology we all would use every day once seemed speculative. Today, you might be hard-pressed to find a machine vision expert who doesn’t believe this. That may represent the view of a biased audience, but as we see computer vision being incorporated even into smartphone apps it’s difficult to argue against the inevitable ubiquity of the technology.

Computer vision is becoming part of the fabric of our society in important ways like improving automotive safety and healthcare, providing intelligent security systems, improving agriculture, and even teaching machines how to think. Embedded and mobile processors allow for the development of ever-smaller platforms. Vision Systems Design has chronicled the development of machine vision systems for over 20 years and the industry will continue to become more innovative and vibrant as our coverage continues.