Lighting and Illumination Choices

Vision System Design’s online Buyer’s Guide lists well over 100 different suppliers of lighting and illumination products. This is unsurprising when we consider how often the importance of lighting as a factor in the success of a machine vision application has been discussed thus far.

Lighting is a pivotal factor in the design of a machine vision system because these systems create images by analyzing the reflected light from an object, not by analyzing the object itself. For this reason, it is important to understand how the material, size, shape, color, and surface finish of the object you are illuminating will affect light reflected off the object, and what challenges these physical characteristics of the object(s) under inspection may pose.

Illumination choices for machine vision system designers now include halogen, incandescent, fluorescent, compact-fluorescent, plasma-type, high-intensity discharge (HID), Xenon, and light-emitting-diode (LED), fiberoptic, and structured light sources.

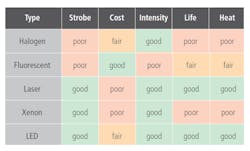

Halogen lights are good for applications where very bright lighting is required. Halogen lights are also limited by their poor strobing capability. They tend to run very hot and lose intensity over time. If halogen light is to be used for an inspection application, it would be beneficial to run the lights at 80% of their maximum power to extend their life, keeping the voltage constant to avoid color changes, and using fiber optics to enable mounting the lamp remotely if the application is sensitive to the heat produced.

Fluorescent lighting sources are relatively inexpensive. They are available in many shapes and sizes and provide diffuse light that minimizes glare. The limiting factors here are that fluorescent lights can’t be strobed, they degrade over time, and it’s difficult to dim them. Fluorescent lights also flicker due to the frequency of the AC power source, which can affect the image quality of vision inspection applications. Using high frequency ballasts can help reduce the amount of flicker but can’t eliminate it entirely.

Lasers are highly collimated light sources which have high intensity, allowing them to be mounted a distance from the object being inspected. A special type of laser called a “diode laser” can be strobed. Lasers are often used to make distance measurements, sometimes in three dimensions, but may not be capable of high accuracies. Lasers are traditionally very expensive and require special safety precautions as they present potential safety hazards. Fiber optics may provide a safer option to provide collimated light if an application requires it.

Many strobing systems that are older employ Xenon lights. Xenon is ideal for strobing because it can provide very high intensity over a short period of time, thus creating the impression of stopped motion. The intensity of Xenon strobes decreases over time, however.

A better alternative is to use light emitting diodes (LEDs). These sources are the most common ones for machine vision applications today. They last a very long time and can be strobed or left on continuously without heat issues. LEDs are also very safe to use, efficient, and can be sourced in virtually any color or specific wavelength.

A lighting technique is a combination of a light source and how it is placed respective to the part and the camera. A specific technique may enhance your image by negating some features within the image or accentuating others.

For example, silhouetting a part to allow measurement of edges while negating the surface details, such as in back lighting, generates instant contrast as it creates dark silhouettes against a bright background. The most common uses for silhouetting are detecting presence / absence of holes and gaps, part placement or orientation, or for measuring objects.

Diffuse, or “full bright field” lighting, is most commonly used on shiny specular or mixed reflectivity samples where even but multi-directional light is needed. Diffuse lighting is commonly implemented with a hemispherical dome or cylinder, or by aiming the lighting on-axis. Diffuse dome lights are very effective at lighting curved, specular surfaces, and are commonly found in the automotive industry.

On-axis lights work in similar fashion for flat samples and are particularly effective at enhancing differentially angled, textured, or topographic features on relatively flat objects. To be effective, diffuse lights, particularly dome varieties, require close proximity to the sample.

Partial bright field lighting is the most commonly-used vision lighting technique. It is also the most familiar lighting we use every day: sunlight is partial bright field lighting.

This type of lighting is distinguished from full bright field in that partial bright field is directional, typically from a point source. Because of its directional nature, partial bright field lighting is a good choice for generating contrast and enhancing topographic detail. It is much less effective, however, when used on-axis with specular surfaces, as this generates “hotspot” type reflections within the image.

Dark field lighting relies on light that is incident at low angles and reflects back from small surface imperfections. Dark field lighting is characterized by low or medium angle of light incidence, typically requiring close proximity to the sample.

In addition to types of lighting and lighting techniques, machine vision system designers may also want to consider lighting controllers.

Any imaging system that has thresholding or is looking for subtle features such as surface defects or color inspection will benefit from improving the repeatability of the light levels. This is where lighting controllers may be useful as they provide consistent illumination.

In some applications, such as line scan inspection systems, it is necessary to continuously illuminate the product being inspected. In other applications, where an area array camera must capture images of objects at high-speed, the LED illuminator may need to be strobed.

In other applications, it may be necessary to illuminate objects with multiple LED lights or with varying illumination intensity to extract the relevant features from the object being imaged. In such cases, intelligent lighting controllers that incorporate selectable intensity, pulse control, speed, and programmable illumination sequencing can meet these demands.

For machine vision applications, lighting controllers that provide constant-current sources are offered by most LED lighting and controller manufacturers since the current flowing through the LED, not the voltage, determines LED brightness. While voltage controllers are available, they are not recommended for machine vision applications since small voltage changes result in large current changes and hence a large change in light intensity. By regulating the current through the LED, constant-current sources ensure that the absolute maximum rating of the LED being driven is not violated and that a predictable and stable luminous intensity is therefore obtained.