Optimizing machine vision lighting for food and beverage inspection

Marc Landman and Paul Downey

Properly inspecting food, beverages, and their associated packaging requires the ability to process images along a wide variety of parameters like size, shape, color, defects, and completeness. To do so, it’s critical to optimize lighting intensity, uniformity, and geometry to obtain images with good contrast and signal to noise. In addition, the varied light absorption properties of organic and inorganic materials can make the selection of the appropriate wavelength for these applications a challenge. To arrive at the best lighting choices, engineers and integrators must understand the essential illumination factors and latest technologies which ensure the best results.

In terms of wavelength, the visible (RGB), near infrared (NIR), and shortwave infrared (SWIR) spectrums of light all may play a role in these inspections. Infrared wavelengths prove particularly effective for the detection of defects and contamination due to foreign bodies, mold, disease, and pests in harvested produce such as fruit, vegetables, rice, corn, nuts, soybeans, and coffee.

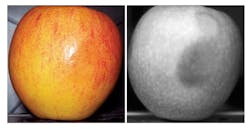

Optimal wavelengths generally exist for the color of each sample. Brown rice, for instance, illuminated at the 1550 nm SWIR wavelength, exhibits strong absorption compared to a sample of red rice (Figure 1). SWIR light effectively measures in greyscale fill levels in glass and IR-transparent plastic bottles, as water-based liquids appear dark under SWIR lighting. (Figure 2). Sub-surface defects such as bruising in fruit, extremely difficult to detect with white light, easily appear under infrared lighting (Figure 3).

Ultraviolet (UV), red, green, and blue lighting can also often reveal more information than provided by white light. LED lighting provides illumination across all these wavelengths and thus accommodates a wide range of inspection types. If samples present multiple types of defects, each most easily detected by a different wavelength than other defects, simultaneous use of multiple LEDs tuned to different wavelengths may prove useful.

Broadband LED hyperspectral lights better serve inspection of heat-sensitive products than the tungsten halogen lights traditionally used for hyperspectral imaging. A large portion of the energy produced by traditional lighting, outside the wavelengths of interest, produces excess heat. Temperatures may exceed 100° C, depending on the specific type of halogen bulb, therefore often requiring the use of active or passive cooling. Broadband LED lights now available which run cool and ensure that the lights do not cook or melt the product or accelerate spoilage.

Foodstuff and beverage packaging can cover a wide range of materials, types, and sizes, each of which may have optimal wavelengths of light for inspection applications. For example, reflections from the packaging material in Figure 4 can interfere with a vision system’s ability to properly read the printed text. Use of red light makes the yellow packaging lighter in the output image so that text on both the white and yellow parts of the package have high contrast against the background.

Related: Deep learning tools inspect food and organic products

Infrared imaging serves food packaging inspection applications by making it easier to read codes and expiration dates. For example, Figure 5 shows the overprinted lid of a yogurt cup with difficult to read expiration date information. Illumination at 940 nm wavelength absorbed by the ink in the printed image and reflected by the ink in the expiration date, provides contrast that makes the date easier to see and image. In addition, the light also reveals defects like tears and holes on the actual surface of the packaging.

Longer wavelengths, or SWIR illumination, is often useful in food and beverage inspections too, particularly those where water or moisture content is involved. A common problem though with SWIR LEDs is the substantially lower intensity compared to standard visible LEDs.

Recent advances in high optical power (HOP) SWIR sources, based on a proprietary material developed by CCS group member EFFILUX, that emits SWIR light 10 times more powerful than other, similar LED sources, provides greatly enhanced contrast for high speed inspection applications. Lighting that incorporates HOP technology can create highly focused SWIR beams as well as large area uniform SWIR illumination and specific projected patterns.

These high optical power lights, compatible with most EFFILUX standard illumination configurations, provide an extensive range of lighting solutions commonly used in SWIR camera applications.

Hyperspectral imaging can also help with inspecting heat-sealed packaging to check for any contamination trapped in the seal itself, which might compromise the integrity of the product. The infrared illumination penetrates the packaging at the seal and the specific wavelength of light under which the contamination appears makes possible analysis of its chemical composition. The analysis then allows the identification and elimination of the contamination source.

After determining the appropriate wavelength of light, the shape of the lighting source, or form factor, also needs selection. LED lights come in ring, dome, coaxial, collimated, bar, and line varieties. In addition to demonstrating the value of red LEDs in this application, Figure 4 also demonstrates the benefit of employing flat dome lighting that produces diffuse light and homogeneous illumination that eliminate the reflections. The flat dome lighting in this example, only 10 mm thick, can fit into limited inspection spaces.

Ring lights can illuminate objects from above, with the camera looking through the center of the ring. This technique illuminates diffuse, non-reflective objects, such as the example in Figure 5, which uses a ring light with IR LEDs. Low angle ring lights, with LEDs mounted at a steep angle on a flexible circuit board within the ring, allow the light to mount much closer to the subject of the inspection. This provides dark field illumination that highlights surface features. The camera only receives light scattered by defects.

Just as important as the shape of the light, how well the LED operates in the operational requirements sometimes necessitated by the need for sterile or clean environments in food and beverage inspection can serve as important criterion for selection. Steam-resistant IP69K enclosures can withstand high pressure and high temperature washdown requirements. IP65 and IP67 enclosures support other washdown systems.

Consistency of light quality proves particularly important in food and beverage inspection because variation in lighting conditions could lead to incorrect pass or fail results. Intelligent lighting solutions, such as CCS’ Fastus system, provide advanced control functionality to account for reduced light intensity over time due to natural LED aging, or changes in external factors like temperature or ambient light conditions, for example. In addition, intelligent lighting solutions can log and record data on equipment maintenance and the consistency of lighting quality, that may meet FDA data tracking requirements.

Marc Landman is the Senior Technical Advisor at CCS America (Burlington, MA, USA; www.cssamerica.com) and Paul Downey is the Marketing Manager for CCS Inc. (Kyoto, Japan; www.ccs-grp.com).