Vendors take a shine to LEDs

Andrew Wilson, Editor, [email protected]

For a number of years the quest to replace halogen-based illumination systems with LEDs has been the holy grail of many a lighting supplier. However, while LED illumination systems do provide longer lifetimes and greater durability than their halogen counterparts, single-die LED devices cannot at present produce the luminous intensity or color temperature needed by system integrators. But recently, at Photonics West (San Jose, CA, USA; January 2006), several companies showed multiple-die LED-based illumination systems that may rival or exceed the performance of lamp-based solutions.

Both Edmund Optics (Barrington, NJ, USA; www.edmundoptics.com) and Schott North America (Auburn, NY, USA; www.us.schott.com) showed prototypes of color LED-based illumination systems that will be available as products later this year. Chris Cummings, R&D engineer at Edmund, spoke of the company’s new EOS technology and how it had been used in the design of a prototype illumination system (see Fig. 1). “EOS technology is used to direct energy from the LED chip at the target,” he says. “150-W quartz-halogen bulbs typically last 1000 hours, but initial testing of the new EOS technology indicates that the LED will be at least two-to-three times brighter than quartz halogen and last 20-50 times longer.”

Figure 1. Edmund Optics fiberoptic illumination prototype uses multiple-LED die and nonlinear optics to create LED light that the company says is two-to-three times brighter than quartz-halogen bulbs.

Upon careful examination of the illumination system, it appeared that Edmund had mounted multiple (at least six) LED die onto a small package roughly less than 1 cm square. According to Samuel Sadoulet, director of product development, the illumination system uses nonlinear optics to tightly focus the light. Further details, Sadoulet says, could not be disclosed.

Similarly, little information was available from Schott North America, which demonstrated a white-light illuminator using multiple LED dies that will be available soon. After disassembling the goose-neck fiberoptic attached to the illuminator, it was clear how the light had been designed. Four similar LED die mounted in a square fashion were remounted on a header to provide the illumination.

Third-party vendors

In the development of these illumination systems, a number of companies are using third-party vendors such as Innovations In Optics (Woburn, MA, USA; www.innovationsinoptics.com). Thomas Brukilacchio, the president, showed an impressive array of LED lighting products targeted toward the machine-vision industry and discussed how such multiple-die LED illumination systems were created.

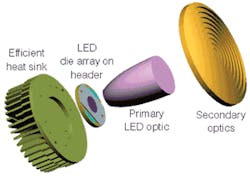

In developing its LumiBright light engines, Innovations in Optics attached LED die or die arrays to a header with high thermal conductivity that can be cooled by conduction, convection, or radiation (see Fig. 2). “But perhaps the most important aspect of the systems is the efficient coupling of the LED output to the target illumination area,” says Brukilacchio.

To perform this function, Innovations In Optics uses a nonimaging optic called a compound parabolic concentrator (CPC). Invented and developed by Roland Winston (ucmeng.net/facultybio/rwinston) when he was a professor of physics at the University of Chicago (Chicago, IL, USA), the CPC concentrates light more intensively than traditional optics. It was designed using the TracePro program from Lambda Research (Littleton, MA, USA; www.lambdares.com) and rendered using SolidWorks from SolidWorks Corp. (Concord, MA, USA; www.solidworks.com).

“To develop a fiberoptic illuminator, this primary optic is all that is required to meet the product specifications. Because the CPC takes the form of a shifted and tilted parabola of revolution, 96% of radiation filling its input aperture falls within the exit aperture, making the CPC a nearly ideal concentrator for LED applications,” Brukilacchio adds.

In addition to developing new LED illumination sources for a number of machine-vision and aerospace applications, Innovations In Optics is working on an MR-16 halogen replacement for fiberoptic illumination sources. According to Brukilacchio, this will be displayed at Lightfair International, to be held in Las Vegas, NV, USA, from May 30 to June 1 (www.lightfair.com).

Currently, the company is looking for interested third parties to market and distribute this lamp worldwide.