Got milk

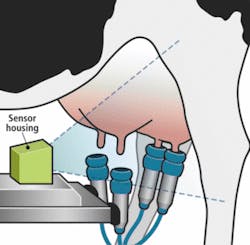

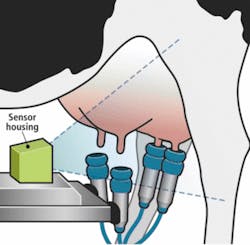

Automated milking in dairy farms not only frees up valuable time for the farmer but can make for happier cows that produce higher yields of better-quality milk. To automatically identify and locate the teat positions on the cow’s udder as it steps into the milking box, teat-finding equipment has relied on laser triangulation and ultrasonic ranging—both with drawbacks such as moving parts and/or laser safety issues. The information derived from such a sensor is used to guide a robot arm to attach milking cups to the teats.

Since cows are highly individual animals in behavior and appearance, a vision sensor must cope with variations in color and a live, moving animal in a naturally dirty environment. It is a complex task, requiring a high degree of accuracy. To develop a new generation of automated milking systems, GEA Farm Technologies (Bönen, Germany) has worked with LMI Technologies (Delta, BC, Canada; www.lmitechnologies.com) to adapt its Tracker 4000 teat-finding sensor, which is based on 3-D time-of-flight (TOF) ranging imagers.

Real-time image-processing algorithms running in the LMI FireSync processor extract teat and milking cup locations from the images, ignoring other objects in the field of view, like a cow’s leg or a swinging tail. Coordinate positions for teats and milking cup locations in a predefined coordinate system are delivered to the robot controller via Ethernet. The vision sensor is mounted on the actuator end of the cup-attachment robot arm and thereby enables a simultaneous verification of the milking cup position before attachment.