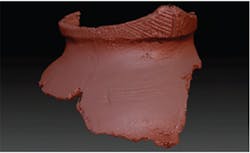

Archaeological collections scanned in 3-D

The Sustainable Archaeology Animation Unit (SAAU) of Sustainable Archaeology has taken steps to make Ontario's archaeological records accessible to researchers, students, and the public by scanning them with a 3-D scanner from 3D3 Solutions (Burnaby, BC, Canada).

Sustainable Archaeology is a research initiative at Western University funded by the Canadian Foundation for Innovation and Ontario Ministry of Research and Innovation. The SAAU, the first animation studio dedicated to archaeology, was established as a joint collaboration between Sustainable Archaeology, the Museum of Ontario Archaeology, and theskonkworks Inc.

Its mandate is to combine 3-D artifact digitization and computer generated imagery to achieve the long term preservation and digital archiving of Ontario's archaeological heritage.

Sustainable Archaeology contacted 3D3 Solutions to propose a 3-D scanning solution that would allow large archaeological collections to be digitized quickly and accurately. The system had to be capable of handling large volumes of artifacts that range in different shapes and sizes, as well as encapsulate their true color and texture.

3D3 Solutions collaborated with Sustainable Archaeology's SAAU personnel to perfect a 3-D assembly line system based on four of its HDI Advance 3D Scanners. The scanners captures 3-D scans from the objects with 3D3 Solution’s proprietary scanning software, FlexScan3D, which is included with each scanner. The software also provides basic post-processing capabilities that merges and aligns 3-D scans into a digital 3-D model.

"From talking to other researchers and from our past experiences, we find that other 3-D scanners normally take a couple of hours to scan one artifact. With the assembly line approach to 3-D scanning we are able to scan an artifact in about 30 minutes which cuts down a considerable amount of time for us. This is very important factor when there is a large collection of artifacts to scan," says Namir Ahmed, SAAU's project co-ordinator.

Details of the system can be found here.

Related items of interest from Vision Systems Design.

1. Kinect used to create 3-D death mask of Newton

Researchers at Microsoft Research Laboratory (Cambridge, UK) have used a Kinect camera to produce the first ever 3-D scan of Sir Isaac Newton's death mask.

2. 3-D wand helps technicians effect auto repairs

Guidelight Business Solutions (Austin, TX, USA) has developed a 3-D vision system for Matrix Electronic Measuring (Salina, KS, USA) that delivers precise measurements of a vehicle's body and engine.

3. 3-D scanner images dental molds

Combining structured lighting, smart optics, and software, a 3-D scanner provides dental technicians with a faster way to image dental molds.

-- Dave Wilson, Senior Editor, Vision Systems Design