AI-Based Machine Vision Boosting Distribution Yard Efficiency

Logistics, the industry of transporting goods and materials, is an enormous business worldwide. In 2023, some 20.2 billion tons of freight estimated at around $18.7 trillion was moved in the U.S. alone, according to the U.S. Dept. of Transportation’s Bureau of Transportation Statistics. Of that, more than 12 billion tons estimated at more than $11 trillion were transported by truck/tractor trailer. And, according to the American Trucking Associations, trucks moved 72.6% of the nation’s freight, by weight, in 2022.

One important link in the supply chain, the distribution yard, seems to be an area that has received great attention in recent years. Distribution yards, the facilities in the supply chain at which tractor-trailers transition goods between logistics center and open road, are significant pain points in the supply chain. Indeed, Terminal Industries (Austin, TX, USA), a company that specializes in machine vision solutions for the logistics industry, estimates that some 90% of all distribution yards in the U.S. do not have adequate technological infrastructure to efficiently handle the volume.

Why the Distribution Yard is a Bottleneck

“When you look at the yard, it’s still a lot of manual processes,” says Michael Plasencia, managing director of RyderVentures and new product strategy for Ryder System (Coral Gables, FL). “It’s somebody with a clipboard checking things through. It’s yard truck drivers moving stuff around a yard.”

The yards—whether in a warehouse, distribution center, or manufacturing facility setting—are generally located in an area that is easily accessible, such as the rear or side of a facility or building, adjacent to or near loading docks, and close to access points and main roads.

Yard operations typically require numerous workers to do many manual repetitive tasks, from walking or cruising the yard to check in, locate, or check out trucks and container trailers, to physically working with and moving them to various destinations in the yard.

At any given time, hundreds of trailers can be onsite, in various stages of loading or unloading, at a distribution yard. Consequently, the task of keeping track of all the trailers 24/7, in all types of weather conditions and chaotic, hazardous environments can be complicated, confusing, cumbersome and dangerous. Reporting, scheduling, locating, and identifying who and what is coming in and out is a monumental task, and human error is the top reason for mistakes in any distribution yard, say those in the know. To automate these operations and improve efficiency, yard managers are turning to the combination of machine vision and AI.

Related:AI and Rugged Edge Computing Fueling Range of Applications

The idea is that a broad view of the yard area using one or many cameras might be used by AI to determine where vehicles are and how they are moving. In the case of autonomous vehicles, these images help determine routes and manage motion through the yard, explains Machine Vision Expert David Dechow, automation solutions architect at Motion Automation Intelligence (Birmingham, AL, USA).

One example, he adds, is vehicle identification and tracking. “Deep learning-based character recognition and OCR is becoming almost a standard,” Dechow says. “Reading the ID of trucks and vehicles for logistics has been implemented for a while, but the improvement provided by the deep learning OCR tools offers greater reliability.”

Another area of interest is the use of AI and vision to provide guidance and obstacle avoidance for autonomous vehicles for various tasks, Dechow says. “Much of the machine/computer vision in these vehicles is proprietary and unique to the vehicle operation, but overall it is not much different from the autonomous vehicles and robots used inside the warehouse or on the plant floor,” he says.

Organizing the Paperwork With AI

Companies such as Outrider (Brighton, CO, USA), EAIGLE (Boston, MA, USA), Ryder System, and Terminal Industries have developed automated, machine vision and AI-based yard management systems, which help yard operators streamline operations and organize workflow.

EAIGLE’s solution is a machine vision and AI based end-to-end platform that integrates into and utilizes existing surveillance camera systems to collect and transmit image data to a computer loaded with AI and machine vision software that processes and uses that data to perform tasks such as locating and tracking every vehicle, asset, and pallet of freight that is processed through a logistics yard.

Ryder and Terminal Industries recently teamed up to put together a system, based on AI/computer vision, that digitizes many distribution yard record-keeping processes.

Initially deployed in one of Ryder’s e-commerce warehouse facilities in City of Industry, CA, in January 2024, the system utilizes off-the-shelf 4k industrial cameras that were integrated into the yard’s existing camera system. AI and machine vision powered software identifies, indexes, and analyzes information from trucks and trailers entering the yard. As trucks enter the facility, cameras deployed near the entrance gate capture alphanumeric information from license plates and transportation department I.D. numbers. The data is then transmitted, via WiFi or 5G, and processed in the cloud.

In addition, the cloud-based system can tap into other outside databases to find and verify data. That means it is much easier and more efficient to handle required regulatory operations, such as compliance reports, as well as simplify and streamline functions such as appointment and scheduling validation and asset availability.

The deployment of this system not only reduces what is essentially a two-step, human error-prone process to a one-step, automated process with a 99% accuracy rate in capturing and identifying transportation department numbers and other such identifying information, but it essentially builds a digital record of every vehicle that enters and exits the yard, Plasencia says.

“I think that's the key here,” he says. “We have a versatile solution that can be applied to so many things, not just one. I think you're starting to see, as these AI models continue to develop and the capabilities improve, the use cases for them getting closer and closer to market,” Plasencia says.

For example, in July 2024, this system was deployed in a Ryder truck rental and maintenance facility in the Dallas-Ft. Worth, TX, area. In this operation, the solution was installed on computer tablets. Employees carried the tablets and used them to capture and process data on available inventory throughout that facility, rather than use stationary cameras deployed around the yard.

The Value of Autonomous Vehicles in Yard Operations

Another area where AI and vision are an increasing presence is in guidance and obstacle avoidance for autonomous vehicles in logistics yards.

For example, Outrider is a company that specializes in building electric autonomous yard vehicles for the logistics industry. These EV trucks are designed to help reduce workload and improve safety for human employees as well as more efficiently locate and move tractor trailers through a distribution yard and get them back out on the road.

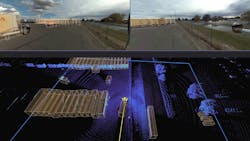

The trucks, which have been deployed since 2017, are designed to find tractor trailers parked in a logistics yard and bring them to loading docks, then return them to available parking areas once the loading/unloading process is completed. Equipped with a vision system that includes LiDAR, radar, and cameras that collect image data such as empty versus occupied parking spaces, trailer identification numbers, standard carrier alpha codes, and other such identifying data, the yard truck’s data is transmitted to a control center computer, usually located and operated on-site in the distribution center. As each yard manages its autonomous yard truck fleet via cloud-based management software or using its own system via API integration, all dispatching, management and orchestration can be handled by one employee.

The solution has been successful in reducing errors, improving safety for human employees, increasing speed and accuracy in identifying and locating trailers, and ultimately, moving freight more quickly in and out of the yards.

“For our customers, one of their main drivers is to reduce trailer turn time, that is, how quickly they can unload, reload, and have semi-trailers back on the road,” says Londonne Corder, chief marketing officer for Outrider (Brighton, CO, USA). “So, we looked at how can we decrease the autonomous turn time? One of the key things was path planning.”

Related: Outrider Develops Autonomous Freight Yard Solution

With that in mind, the company has focused on further developing AI algorithms to enhance the system’s ability to move through the yard even more quickly and efficiently, all the while maintaining safety, she says.

Before, the truck, connected wirelessly to the yard’s operational computer system, could navigate predetermined paths around the yard, such as from a specified loading dock to the location of a parked trailer. Now, rather than simply traveling along a predetermined route to move from point A to point B, the system “plans” each trip as it goes along, avoiding potential hazards, even re-routing itself if necessary. The result, says Corder, is that the speed of trailer turnaround on the yards where this system is deployed by up to 10 times faster than before, all the while maintaining very high safety protocols, she says.

“We don’t just rely on the AI for that; we also have onboard redundant safety mechanism as well,” she notes.

Related: The Need For AI and Data in Fleet Management

While Outrider’s customers are under non-disclosure agreements and cannot be named, Corder says they are all Fortune 100 and 500 companies that represent some 20% of the yard truck market in the U.S. She also points out that the ROI works out favorably for the customer.

“They typically can see as much as a 40% cost savings in a payback period under two years,” Corder says.

Outrider Using AI to Teach Trucks to Drive Themselves

Outrider’s autonomous electric yard trucks, deployed in distribution yards since 2017, use a vision system consisting of cameras, LiDAR, radar, and AI-based machine vision software, to identify, locate, and move trailers on those yards. During that time, those trucks and their vision systems have collected a tremendous amount of image data from those yards, says Outrider Chief Marketing Officer Londonne Corder.

So, the next step in the development of the system, Corder says, was to take all the data Outrider has collected and develop advanced reinforcement learning models for theautonomous vehicle systems. To build these models, Outrider utilized millions of yard-specific data points gathered from numerous complex busy distribution yards across a number of different industries, she says.

The models are built and tested in simulation, then extensively tested at Outrider’s test site before being deployed on a customer’s site, she says.

“The foundation of AI is having a big enough data set to start training our neural networks,” Corder says. “We build a curriculum for our reinforcement models with increasing levels of difficulty and use that to train our system about what behaviors we prefer it to do, such as following traffic rules, maintaining safe distances between vehicles, and discouraging undesirable behaviors.”

The system learns to plan each trip as it goes along, rather than simply follow a predetermined path to move from Point A to Point B. This is because the autonomous yard truck will likely encounter a situation that may cause it to deviate from the original path. So if, for example, a yard truck is navigating from a loading dock to a parking area, and it encounters an incoming semi-truck coming toward it, the yard truck will “know” to take certain actions to maintain safety while still moving efficiently to its destination. In addition to the algorithms, the yard truck is also equipped with redundant safety mechanisms on board as well.

“It gives us the ability to move the freight more efficiently through these ever dynamic, complex, busy distribution yards,” Corder says. “It gives us greater speed and agility, all while being safe in doing so.”

About the Author

Jim Tatum

Senior Editor

VSD Senior Editor Jim Tatum has more than 25 years experience in print and digital journalism, covering business/industry/economic development issues, regional and local government/regulatory issues, and more. In 2019, he transitioned from newspapers to business media full time, joining VSD in 2023.