Digital video recorder captures Camera Link images

Camera Link cameras and frame grabbers are now being used in many industrial and military applications. In many of these systems, sequences of captured images are processed at high-speed on multicore-PC-based systems, any defects rapidly located, and a pass/fail decision made whether to reject or accept the product being inspected.

Although these PC-based systems can capture and analyze images, they are generally not used to simultaneously store image sequences since any interrupt on the PC bus would result in dropped frames and may reduce image-processing speeds. In some image-processing systems, it is necessary to capture sequences of Camera Link data so they can be later used to troubleshoot industrial machinery or in simulation systems to emulate high-speed procedures.

In a system developed at Boeing (Chicago, IL, USA; www.boeing.com), Camera Link cameras used with fiber-optic extenders are used to monitor a gimbaled flying boom containing a fuel pipe that is attached to the rear of a tanker aircraft in flight. By monitoring the operation of the fuel nozzle at the end of this fuel pipe, the crew can dynamically position the nozzle to the receptacle in the receiver aircraft, ensuring proper mating of the fuel nozzle.

Although successful, Boeing required a method to simultaneously capture long image sequences from the cameras so that they could be later used in ground-based flight simulation systems.

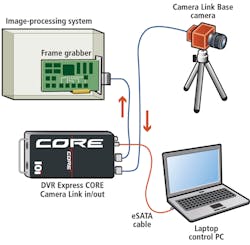

The company called upon IO Industries (London, ON, Canada; www.ioindustries.com) to develop an image-storage system for this very purpose. This development led to the creation of a portable, rugged DVR system. Dubbed the DVR Express CORE I/O system, the unit is an independent digital video recorder (DVR) interfaced between the Camera Link Base cameras used on the aircraft and the PC-based image-capture system (see figure). The base model of the $5000 unit contains 2 Tbytes of image storage, allowing 24-bit image data running at 85 MHz from a Camera Link Base camera to be transferred to the system at rates up to 250 Mbytes/s.

“In a typical configuration,” says Adam Little, an applications engineer with IO Industries, “the system can be used to store up to 18 hours of Camera Link images of 1024 × 1024 × 8 bits running at 30 frames/s.” Because the DVR Express CORE I/O system is hot-swappable, units can also be interchanged in-flight should the need arise.

To export Camera Link data to the DVR Express CORE I/O system, IO Industries employs its streaming video control software running on the host PC.

The DVR Express CORE I/O system provides adequate image storage for Boeing’s in-flight recorder, but it can also be used as a frame buffer for image processing or as a Camera Link repeater. In such a configuration, it may be used in industrial machine-vision applications.

Cognex (Natick, MA, USA; www.cognex.com) uses IO Industries hardware and software in parallel with its own systems for data recording of web inspection. “In this way,” says Little, “web-inspection system developers can provide a full video record to the customer, should there be any questions regarding defect detection.”

“Because the unit also features a 3-Gbit/s external SATA interface and optional 12-Gbit/s download module,” says Little, “it can also be interfaced with very large data storage systems from such companies as Infortrend [Taipei, Taiwan; www.infortrend.com] and Promise Technology [Milpitas, CA, USA; www.promise.com], allowing months of imaging data to be recorded.” This feature is useful for system integrators who currently deploy Camera Link-based systems who may wish to add data tracking capability to their systems.

The DVR Express CORE I/O system presently supports Camera Link Base, HD-SDI, and 3G-SDI interfaces; the company is looking to expand the offering to encompass newer interfaces such as CoaXPress and HSLINK standards as they emerge.

More Vision Systems Issue Articles

Vision Systems Articles Archives