Thermal camera helps analyze parts at over Mach 5

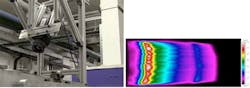

Manchester University (Manchester, UK) researchers are using a thermal imaging camera from FLIR Systems (Wilsonville, OR, USA) to examine the performance of aerospace components in a wind tunnel.

The wind tunnel at the university is one of the few experimental facilities in Europe that can reach Mach numbers higher than 5.

According to Professor Konstantinos Kontis, head of the Aerospace Research Group at Manchester University (Manchester, UK), the prolonged exposure to friction induced heat caused by the air flowing across the surface of an aircraft traveling at Mach 5 can be detrimental to the structural integrity of the material used in aircraft components. It is therefore important to test such components extensively before they are deployed in the field.

To capture thermal maps of the entire surface of the parts under test in the wind tunnel, Professor Kontis chose the FLIR SC655 thermal imaging camera which contains an uncooled microbolometer detector that produces thermal images at a resolution of 640×480 pixels and has a thermal sensitivity of 50mK (0.05°C).

The full resolution can be captured at a frame rate of 50 fps, but it also provides high-speed windowing modes that allow the operator to increase the frame rate to 200 fps with a resolution of 640×120 pixels.

To capture the thermal footage and perform the initial analysis of the temperature data, Professor Kontis and research associate Dr. Erinc Erdem use FLIR ResearchIR software.

"We use it to capture the data, define special regions of interest and export the temperature measurement strings to third party software for an in-depth analysis of the data," says Dr. Erdem.

On one end of the wind tunnel there is a chamber capable of containing pressurized air up to 15 bar, 15 times the regular atmospheric air pressure. At the other end is a vacuum tank which is brought to 1 mbar, one thousandth of regular atmospheric air pressure.

In between the two is the test chamber where the test object is placed. As the pressurized air travels from the pressure chamber into the vacuum chamber, it passes the test object with a speed of about 4000 kilometer per hour, similar to traveling at Mach 6.

The FLIR SC655 thermal imaging camera is located on top of the test chamber, looking in through a Germanium window. This allows the camera to accurately map the thermal hot spots caused by the air friction, without being subjected to the force of high velocity airflows.

The knowledge gained by the wind tunnel tests will help designers of high speed aircraft and re-entry space vessels that need to bring payloads to orbit and return to Earth.

Recent articles from Vision Systems Design on the use of thermal imaging that you might also find of interest.

1. 'Super-framing' increases the dynamic range of thermal imagers

A technique called super-framing extends the effective scene brightness of a thermal image while maintaining its thermal contrast.

2. Multicamera system performs motion analysis

By capturing data in the visible and IR spectra, reconstructed 3-D image data can both model the human form and map the thermal energy emitted from the human body.

3. Vineyard monitoring system combines global positioning and NIR imaging

Spanish researchers have developed a ground-based machine-vision system that combines infrared (IR) imaging and a global positioning system (GPS) that promises to reduce the cost of crop monitoring.

-- Dave Wilson, Senior Editor, Vision Systems Design