FireWire cameras embed processors, FPGAs

To reduce the cost ofdigital cameras, a number of manufacturers are using off-the-shelfprocessors, FPGAs, andstandard interfaces such as FireWire, Camera Link, and Gigabit Ethernet. Adopting such a design philosophy allows a number of different sensors to be used and permits camera vendors to offer different products with similar hardware designs.

In August 2004, for example, Imaging Solutions Group (ISG; Fairport, NY, USA; www.isgchips.com) used the 1394a FireWire implementation in its latest 2k × 1 linescan camera, the LightWise LW-SLIS-2048. At that time, Kodak’s Image Sensor Solutions Group (Rochester, NY, USA; www.kodak.com/ go/imagers) also introduced a camera reference module that can be programmed over Camera Link to demonstrate the features of its KAI-0340 CCD (seeVision Systems Design, August 2004, p. 14).

Now, after being purchased by John and Peggy Moore, Dage-MTI (Michigan City, IN, USA; www.dagemti.com) is set to roll out a number of FireWire cameras based on a programmable RISC processor and an embedded FPGA. According to John Moore, president, the company will initially develop three cameras around the 1394a interface. These will be modular in design, consisting of a 3-in.-diameter base sensor module, a sensor and timing module, and a processing/interface board.

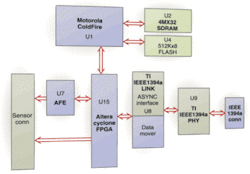

The cameras, tentatively dubbed the Phoenix line, will support Kodak’s KAI-0340, KAI-2020, and KAI-4021 devices and offer resolutions of 640 × 480, 1600 × 1200, and 2k × 2k, respectively. In developing the cameras, Tom Monroe, senior design engineer with Dage-MTI, chose a number of off-the-shelf components including PHY and LINK chips from Texas Instruments (TI; Dallas, TX, USA; www.ti.com) for the 1394a interface (see figure).

FireWire interface

“In developing the FireWire interface,” says Monroe, “we considered a number of different options including using the TI 1394b PHY/LINK chipset. Unfortunately, because the 1394b LINK asynchronous interface chip was designed with a PCI interface and no local bus interface (the data mover port), it was unsuitable for this design. We were informed by TI that such a (1394b) part was more than a year away.”

Because of this, Dage-MTI implemented the interface using TI 1394a PHY and LINK parts, resulting in 400-Mbits/s data-transfer speeds from the camera module. Interestingly, in the ISG design, the company implemented the link-layer controller in software on an 8051 microcontroller from Cirrus Logic (Austin, TX, USA; www.cirrus.com), allowing the 1394a interface to be implemented with the 8051 and an external PHY chip.

In the Dage-MTI design, an FPGA from Altera (San Jose, CA, USA; www.altera.com) is programmed using an embedded Coldfire processor from Motorola (Schaumberg, IL, USA; www.motorola.com), which controls an analog front end (AFE), the AD9949, from Analog Devices (Norwood, MA, USA; www.analog.com). This AFE provides the timing for the vertical and horizontal clock drivers of a number of Kodak sensors including the KAI-0340, KAI-2020, and KAI-4021. A correlated double-sampled (CDS) 12-bit digital output is then provided to the Cyclone gate array.

“Since only one tap of the CCD devices was used,” says Monroe, “it was not necessary to use a second AFE, as is the case in Kodak’s Camera Link reference design.” In the development of the camera, Monroe and his colleagues used Motorola’s ColdFire embedded 32-bit RISC processor to control camera timing, data transfer, and interface functions.

“Although use of a 32-bit RISC processor may seem like overkill for this application,” says Monroe, “our previous experience using the device is helpful in bringing Dage-MTI’s cameras to market a lot faster.” Running their own embedded real-time operating system (RTOS), the processor and FPGA firmware can be upgraded over the camera’s FireWire interface. “As the camera is IIDC (DCAM) compliant,” says Monroe, “the camera control registers appear as a standardized memory map that the host PC can access.”

Because the design of the cameras is modular, different types of interfaces such as Camera Link, USB, or Gigabit Ethernet can be added as customer demands dictate. Rather than redesign each camera, only the interface board need be swapped. Planned for introduction at next year’s Vision show, Dage-MTI’s new cameras will be priced at less than $10,000 and will include a Visual C development environment and a GUI to set camera parameters.