IMAGE CAPTURE: Novel technology lowers the cost of hyperspectral imaging

In many industrial and medical vision applications, it is necessary to precisely discern the spectral properties of materials. In cotton sorting, for example, it may be necessary to sort good cotton fibers from any contaminants such as dirt or foreign fibers. In medical imaging, these spectral characteristics can be used to determine skin pigments and accurately predict different types of skin cancer.

To perform these tasks, the spectral signature of the material or objects must first be determined. Then, by comparing spectral signatures at different wavelengths, the materials can be analyzed. To date, a number of different methods exist to measure the spectral reflectance curve of reflected light at numerous points across the spectrum (see “Imaging systems tackle color measurement,” Vision Systems Design, August 2007).

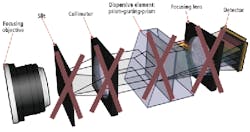

One of the most accurate ways to perform these measurements is by using a hyperspectral imaging camera. Such sensors often measure hundreds of wavelengths in narrow bandwidths to cover the entire spectrum in a contiguous manner. Spectral cameras such as those offered by Specim (Oulu, Finland; www.specim.fi) employ an objective lens in which light is first focused onto a narrow slit and then collimated through a dispersive element.

This dispersive element has the effect of splitting the light into a series of narrow spectral bands that are then focused onto an area-array detector. In this way, the spectral properties of the single line of light at narrow, contiguous bands are captured.

Since the cameras image single lines of light at a time, they must be operated in a push-broom or linescan fashion in which either the object to be measured is moving across the field of view of the camera, or the camera is moved across the field of view of the object. In this manner, a hyperspectral cube can be created that represents a stack of 2-D images, each of which contains specific information about individual frequency bands.

Because these cameras use a number of optical elements to perform this task, they are often more expensive and slower than techniques that use multispectral techniques to capture a few, often noncontiguous data sets. For this reason, researchers at IMEC (Leuven, Belgium; www.imec.be) have developed a novel way of producing hyperspectral imagers that both lower the cost and increase the speed of hyperspectral imaging. The cameras were on display during VISION 2010 in Stuttgart, Germany.

To do so, two approaches are currently being developed. While the first still employs an objective lens, the narrow slit and collimator become optional and the dispersive elements and focusing lens are replaced by an optical fixed wedge structure that is post-processed onto the imager. According to Francesco Pessolano, manager of the NVISION program at IMEC, this has the effect of splitting the light into several spectral bands while eliminating the need for expensive optics.

In the second approach, the slit and collimator are also replaced with a tunable microelectromechanical system (MEMS). When this is used in conjunction with an objective lens, the other elements can be replaced, resulting in a faster, more compact, frame-based hyperspectral camera (see figure). According to Pessolano, such devices can operate at approximately 10k lines/s compared with the 0.2k to 1k lines/s achievable with current implementations.

Depending on the nature of the application, different sensor/and optical wedge structures can be implemented. IMEC is currently in discussions with third-party developers of cameras and embedded systems to tailor the technology for applications that may include a portable, handheld hyperspectral device for the analysis of skin lesions.