Digital x-ray system increases productivity

By Lawrence J. Curran,Contributing Editor

Direct digital radiography is becoming an attractive alternative to conventional film-based x-ray imaging as a medical diagnostic tool. Digital x-ray images eliminate the need for costly film cassettes, film processing, and film storage. The images are immediately available over a global network accessible by physicians in remote locations, allowing them to consult in diagnoses more efficiently.

Swissray International Inc. (Elmsford, NY) has tapped this growing market with its digital x-ray systems, which are based on patented x-ray detection technology. Rex Harmon, vice president of marketing, says the company has built more than 200 direct digital radiography (ddR) systems, of which about 150 are the ddRMulti-System. This all-purpose model can examine patients in an upright, seated, or recumbent position.

One Swissray client—a 231-bed hospital in Georgia—has experienced a substantial boost in patient imaging productivity since adopting digital radiography. Former conventional x-ray procedures at the Houston Healthcare Complex (HHC; Warner Robins, GA) required more than 20 steps to process a patient's film-based x-ray examination. Now, this process has been slashed to six steps with direct digital radiography. Moreover, technician productivity has been hiked by an estimated 300%, according to Felipe Patino Jr., director of radiology services. Further, there's no need to store and handle chemicals because there's no wet film processing, and patient exposure to radiation is decreased.

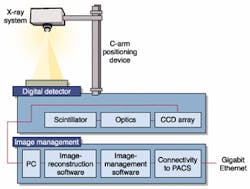

FIGURE 1. The ddRMulti system essentially consists of an x-ray system source and a patented digital detector. X-rays are generated by accelerating electrons into a tungsten target within a special x-ray tube, which emits an x-ray beam. The collimated beam irradiates a patient and is absorbed to varying degrees by the patient's tissue. This process produces x-ray shadows, which pass to the detector section. The scintillator converts x-rays to light, and the optics block focuses four CCD cameras on the scintillator to capture a digital image. The digital image is transferred to the PC for processing and local display and to the Gigabit Ethernet network for remote access by a diagnostician.

Swissray's Harmon says the principles of ddR are the same as for conventional radiology: the ddrMulti-System generates x-rays by accelerating electrons into a tungsten target within a special x-ray tube, which, in turn, emits an x-ray beam. The beam is collimated and directed toward the patient.

The beam travels through the patient and is absorbed to varying degrees by the patient's tissue. This process creates x-ray shadows and emerges as an "image in space." After detection and recording, the image provides an anatomical picture that is ready for diagnostic review by a radiologist.

The important difference between ddR and conventional radiography is that the ddR detector technology converts x-rays directly into a digital image. This method eliminates the time and costs associated with the usual intermediate image-processing steps, such as are used in film or phosphor-plate processing.

PRIMARY SEGMENTSSwissray's ddR systems comprise two primary segments —the x-ray-generating apparatus and the image-detection apparatus (see Fig. 1). The x-ray-generating apparatus includes a voltage-boosting transformer, a control console for setting voltages and current, and a collimator to shape the beam. Those components are all purchased and integrated by Swissray, Harmon says.The image-detection segment contains the system's fundamental contribution, which was pioneered by Swissray founder, chairman, president, and chief executive officer Reudi Laupper. He developed a prototype system in 1993 and first demonstrated a complete version in 1995. His patented contribution is embodied in the system's AddOn-Bucky detector. The patent covers the detector's optical arrangement and method for electronically detecting an x-ray image. AddOn-Bucky is the key component in each of the company's four ddR system models: ddRMulti, ddRCombi, Modulaire, and ddRChest. The Houston Healthcare Complex uses two ddRCombi units.

The detector section includes a scintillator that converts the x-ray image in space to light "using essentially the same principles as Dr. Roentgen, the x-ray pioneer, did in 1895," Harmon says. The scintillator consists of a layer of crystals made of a proprietary material deposited on a polyester base. Also included in the detector is an optics block. This block incorporates four angled mirrors that work much like a periscope and focus four CCD cameras on the scintillator, according to Harmon.

These cameras, from Eastman Kodak Co. (Rochester, NY), incorporate the company's Blue Plus CCDs, which offer a resolution of more than 5.2 million pixels. The CCDs provide 70% quantum efficiency in the green and red portions of the spectrum, which increases signal strength without any increase in sensor noise. They were developed for use in low-light-level applications, including astronomy. Their efficiencies combine with that of scintillator plate result in a 50% reduction in a patient's x-ray dose compared to earlier Swissray ddR systems. With an equivalent film speed of 1600, the CCDs are fabricated of indium tin oxide, along with integral color filter arrays.

GETTING THE PICTURE"When an exposure is made, the scintillator glows, and the four cameras visualize the scintillator through the optics block and capture the information within a millisecond or as long as two or three seconds," Harmon says. The refresh rate between exposures is approximately five seconds. The captured pixels move from the CCDs to the SwissVision image-processing system. This system comprises a Windows 2000-based x-ray-acquisition and postprocessing workstation built around an IBM-compatible PC with a 21-in. video display (see Fig. 2). The PC uses a 1.4-GHz Intel Corp. (Santa Clara, CA) Pentium 4 microprocessor. Harmon points out that the workstation applies Swissray's proprietary organ-specific image-processing algorithms, which enable the fully processed digital images to be displayed on a monitor in diagnostic quality within seconds of capture (see Fig. 3).The workstation offers Ethernet and DICOM (digital imaging and communications in medicine) interfaces.Additional major components in the ddRMulti-System include a Swissray GEN-X 80-kW frequency generator and a high-speed, rotating anode x-ray tube: a 36/100-kW SRX 21-HS-1 from Varian Medical Systems Inc. (Salt Lake City, UT). To take a chest x-ray, for example, the generator bombards the anode target with 500 mA of current at 120 kV for about 10 ms, causing the tube to emit x-rays.

A computer-controlled, motor-driven, floor-mounted Swissray-built C-arm positioning device attached to the ddRMulti-System allows both vertical- and horizontal-oriented examinations. The x-ray tube is located at the end of the C-arm so that it can be centered to the digital detector segment in any position. A Swissray IGS 1000 floating-top table is available for use with patients requiring horizontal positioning.

Designing and implementing the AddOn-Bucky detector was a major challenge the company faced in developing the ddR technology. Says Harmon, "How we arrange the CCDs to look at the scintillator is proprietary and patented."

Overcoming noise was also a problem. It required selection of the right elements and getting them to generate enough light without delivering a signal that carried a risky radiation dose. "The Kodak CCD technology made a major contribution, which helped to get more light from the signal," Harmon says. The CCD chips are mounted on a substrate that dissipates sufficient heat to lower their operating temperature and boost their signal-to-noise ratio.

A Swissray ddR system can become a node on a Picture Archiving and Communication System (PACS), which would permit the distribution of image and related information over wide- and local-area networks. "Our system is a direct image-capture device," Harmon points out, "and needs a network behind it" to provide real-time collaboration among geographically dispersed physicians. Swissray provides networking capability if users aren't already equipped with PACS. The Houston Healthcare Complex PACS system links the complex's three sites over a Gigabit Ethernet network.

EASY INTEGRATIONHouston Healthcare Complex's Patino was pleased with the ease of integrating the two ddRCombi systems into the HHC facility—one in January and another in June. The complex comprises two hospitals with a total of 231 beds, plus an outpatient clinic, all of which serve a population of about 118,000.Two years ago, Patino undertook a PACS-implementation project to make the film operations more efficient. He opted for Swissray because "Swissray's technology was proven, and we were comfortable with it. Other technology wasn't yet proven." Nor were there any problems in integrating the ddR systems into HHC's facilities. "That was one of the best things about the choice," Patino stresses. "Swissray came in, and within one week we had images going across the network. It was essentially a plug-and-play exercise," which didn't require additional equipment. The Gigabit Ethernet network was installed earlier by EMC Corp. (Hopkinton, MA) into which MarkCare Medical Solutions (Bloomfield, NJ) integrated HHC's PACS.

The first ddRCombi system was installed in the 186-bed Houston Medical Center, which houses an emergency room, and the second such system went to work in the 45-bed Perry Hospital several months later. Before the ddRCombi was integrated into the PACS, only about 30% of emergency cases had x-ray examinations performed in the emergency rooms (ERs), Patino points out. That translated into a heavy workload in the larger main radiology department, and the need to transport patients to that location from the ERs. "Now 99% of all studies are done in the ERs, and images are available rapidly to the ordering ER doctor [over the network], which is a big benefit," he emphasizes.

Patino says that using digital radiography has boosted technician productivity "dramatically," by some 300%. Furthermore, use of high-technology digital radiography provides an important intangible in that "it represents a marketing tool to retain and attract technologists; we have close to full staffing in a time of severe personnel shortages."

Company InformationEastman Kodak Co.Rochester, NY 14650Web: www.kodak.comEMC Corp.

Hopkinton, MA 01748

Web: www.emc.com

Houston Healthcare Complex

Warner Robins, GA 31093

Web: www.hhc.org

Intel Corp.

Santa Clara, CA 95052

Web: www.intel.com

MarkCare Medical Solutions

Bloomfield, NJ 07003

Web: www.markcare.com

Swissray International Inc.

Elmsford, NY 10523

Web: www.swissray.com

Varian Medical Systems Inc.

X-Ray Products Division

Salt Lake City, UT 84104

Web: www.varian.com