Cameras check ships' coatings

Researchers at the Naval Research Laboratory have developed a new system to inspect the exterior coatings of ships.

Current methods of performing inspections of ship surfaces are slow, labor intensive and highly subjective. They require technicians to manually measure coating thicknesses as well as visually inspect surfaces for corrosion damage and blistering below the surface.

NRL's new streamlined process uses two digital cameras to capture detailed images of a vessel. The images can be collected either from the side of a pier or from a patrol boat at distances between 100 and 200 ft from a ship.

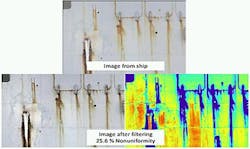

The resultant sets of images are next uploaded to an NRL developed software application that automatically quantifies the condition of the surface coatings.

The software -- referred to as the Automated Freeboard and Topside Coatings Analysis Toolset (AFTCAT) -- consists of a group of image processing and data interpretation algorithms.

The Topside Corrosion Detection Algorithm (TCDA), one of the AFTCAT algorithms, can automatically assess the extent of corrosion damage and degradation. Other algorithms assess coating color uniformity and the extent of coating failures due to flaking and delamination and blistering.

Only two trained technicians are required to collect the image sets, while an additional technician is needed to run the AFTCAT on them and automatically generate and complete the inspection reports.

The research team expects that the new system will enable all the surfaces of a vessel to be conducted during a total of 10 man-days, including the generation of the inspection report, as opposed to the 65 man-days that are presently needed to perform the task.

-- By Dave Wilson, Senior Editor, Vision Systems Design