Detector array lowers 3-D x-ray imaging cost

First established in 1996 to exploit research at Nottingham Trent University (NTU; Nottingham, UK; www.ntu.ac.uk) on stereoscopic x-ray imaging technologies, Image Scan Holding (Melton Mowbray, UK) original products were developed for airport-security systems. One of these products, the AXIS3D, is a stereoscopic x-ray system designed to enhance the screener/system interface and was developed for baggage screening in secured entry applications. It is now distributed in the aviation security market through Rapiscan (Crawley, UK; www.rapiscan.com) as the 3D20 x-ray screening system.

At this year's IPOT show in Birmingham, UK, Image Scan Holdings announced the formation of a subsidiary, 3DX-RAY (Melton Mowbray, UK; www.3dx-ray.com), to offer 2- and 3-D x-ray cameras and technology to OEMs, distributors, and end users in industrial inspection. At the show, the subsidiary announced the DEX flexible x-ray imaging camera technology aimed at industrial inspection applications.

Offering customers access to x-ray source, detectors, computer interface, and a software framework, either as a complete system or on a modular basis, the DEX-camera technology is completely scalable and can be optimized for any tunnel size, ranging from about 10 × 10 mm to greater than 2.5 × 2.5 m. The resolution capability for any tunnel size can be varied to suit the requirements of a given application.

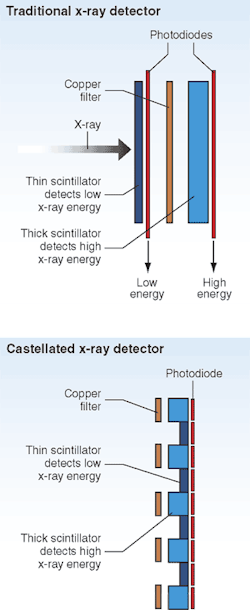

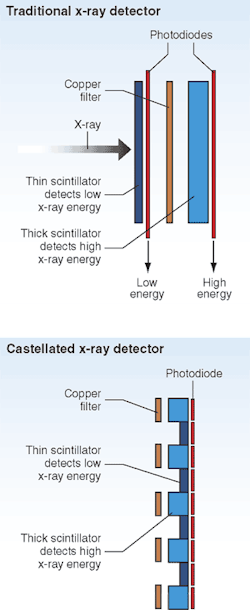

3DX-RAY 2- and 3-D x-ray cameras range from less than 10 × 10-m to greater than 2.5 × 2.5-m tunnel sizes and are designed for industrial x-ray inspection. A standard scintillator/diode approach was abandoned for a novel castellated design (bottom) that integrates low- and high-power detectors while reducing the scintillator/detector count.

Simon Godber, technical director of 3DX-RAY, says, "Traditional x-ray detectors produce images that are purely two-dimensional, monochrome in nature, and provide no indication of material content. 3DX-RAY can offer camera systems that detect different x-ray energies for broad classification of material within the object to be inspected and can accomplish this in 3-D with multiview x-ray camera systems. Materials discrimination can be achieved by using x-ray scintillators of different thickness, sandwiched between photodiode arrays.

In operation, x-rays will strike the first scintillation level, which has been designed to absorb lower-energy x-ray emission, and emitted photons from this scintillator will be detected by an adjacent photodiode. The remaining x-ray energy, being able to pass though both the lower energy scintillator and an attenuation filter, pass through to a scintillation material optimized to absorb a different energy band, where photons are again emitted and detected by a second photodiode array. In this way, such devices can discriminate between different types of material, such as wood and metals, meat and bone, and glass and fluids present in the scanned object. This discrimination is achieved at a device level and is not dependent on associated software.

"To build an array of such detectors," says Godber, "scintillators and photo-diodes are usually butted together in a linear array with two such arrays needed to detect different levels of x-ray energy. However, early in the development of 3DX-RAY camera technology, it became obvious that using conventional approaches to the design of a 3-D x-ray detector would mandate the use of twice the number of detector arrays, dramatically increasing the cost of the final product.

To overcome this requirement, 3DX-RAY has developed a novel dual-energy detector array, known as a castellated detector because of its castle-like structure. The detector structure uses half the number of detector elements used in alternative materials discrimination-capable detector arrays, while maintaining the same resolution capability. "Because of this," says Godber, the 3DX-RAY x-ray cameras can be offered at comparable prices to those of 2-D systems.

The DEX camera is an integrated unit comprising an x-ray source and one or more detector arrays mounted on a support frame. When integrated into an imaging system, objects to be inspected move continuously through the camera, generating either real-time 2-D or 3-D x-ray images. DEX x-ray-detection systems can also be sold as individual components to OEMs, where the data stream from the array can be integrated with existing software packages through a proprietary USB 2.0 interface card.

An integrated self-contained unit in a shielded housing contains the x-ray source, detectors, and preprocessing electronics linked via a USB 2.0 interface and power cable to the system's control unit and power supplies. According to Godber, the single-unit price of the 3-D camera frame, detector board, and application software is approximately £40,000 ($73,000). For a 2-D version, the single-unit price is about £25,000 ($45,600).