An Ethernet-based infrared camera system checks molten steel vessels to detect wear and prevent accidents

Winn Hardin, Contributing Editor

In the dark hours of New Year’s Day in 2006, a steel plant in Duisburg, Germany was transporting molting steel from the oven to the converter in a 280-ton capacity ladle when the ceramic brick refractory materials protecting the vessel from the 1500°C molten steel gave way. The molten metal ate through the steel ladle in a few seconds, spilling red-hot liquid metal across the plant floor. Wiring, equipment, and productivity were instantly destroyed, resulting in months of downtime and more than $20 million in repairs.

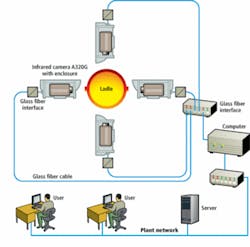

The operators of ArcelorMittal’s steel plant in Eisenhüttenstadt (Brandenburg), Germany want to make sure it never faces the same fate. To eliminate this threat, two systems of infrared (IR) cameras were installed, connected via optical fiber to a remote Gigabit Ethernet switch connected to a standard 19-in. industrial PC running Automation Technology’s IrMonitor multicamera machine-vision utility software. The systems automatically detect ladles and torpedo cars as they move molten steel around the plant, searching for weaknesses in the protective refractory materials before they create a safety and productivity problem for one of Germany’s most advanced steel plants (see Fig. 1).

null

A better NDT

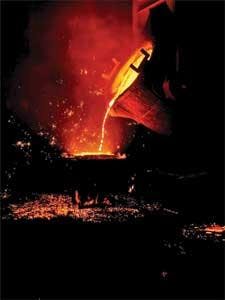

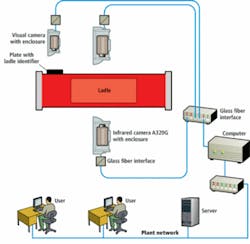

Ladles and torpedo cars are used to transport molten steel from the oven to the converter. Molten steel is poured into ladles that are suspended from cranes, which then carry the ladle to torpedo car for rail delivery to the converting plant where the steel is formed into rolls, bars, or other shapes (see Fig. 2).

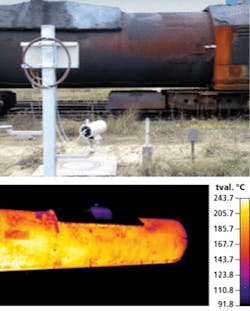

FIGURE 2. Torpedo cars carry thousands of tons of molten steel to the converting plant for final processing. Two IR cameras monitor conditions in a car.

Each ladle and torpedo car is lined with ceramic refractory bricks that can handle the 1500°C+ temperature of the molten steel. Each time the refractory materials come into contact with the molten steel, some of the material is burned away, thinning the refractory wall. If the wall becomes too thin, the molten steel can cause the bricks to crack, quickly melting the ladle. Refractory materials can withstand incredible heat but do not handle physical shock very well. When the 200 tons of molten metal suddenly loses the supporting ladle, what began as a gradual “thinning” can become an immediate safety problem.

“Mostly, our system is a safety system to protect personnel and equipment, but a second reason is to allow the plant to use the vessel as long as possible while staying within safe operation,” explains Michael Wandelt, managing director at system integrator Automation Technology. “When you pull a ladle from production, it costs $60,000 to renew the refractory lining. So the producer wants to use the ladles as long as possible but also to be absolutely sure that the metal won’t break through.”

OpNets for noisy environments

Each ladle is driven by a crane operator from the oven to the torpedo car loading area. The path is constant, but factors such as the specific height and movement of the ladle in the air vary from ladle to ladle.

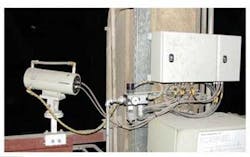

Automation Technology installed four FLIR Systems A320G IR cameras at even intervals surrounding the ladle transport path. As the crane carries the loaded ladle, it passes in front of each camera. Digital temperature images are transmitted constantly from the camera, across 2 m of standard Cat6 copper cable to a junction box. The junction box houses a Microsens MS4000196 Gigabit Ethernet optical fiber converter, which carries the digital image files 350 m to the plant control room without concern for interference from EMI caused by sources such as motors or high-voltage lines (see Fig. 3).

The junction box also houses proprietary electronic controls for a fail-safe air-conditioning system that circulates cooled air around the camera, which is mounted in a double-walled enclosure with germanium optics to allow IR light transmission. A thermocouple inside the enclosure monitors the temperature, and the electronics control the air conditioning system for cooling the enclosure. The Microsens MS4000196 transmits the images and temperature data over the optical fiber to the control room while receiving remote camera control commands from the control room as necessary.

Each of the cameras has a junction box and operates independently of the other three cameras. In the control room two Intel Pro/1000 MF dual-port server adapters installed in the industrial PC collect the data coming over the optical fiber from the four cameras. On the PC the temperature images are evaluated automatically in real time by Automation Technology’s IrMonitor software.

Intelligent ROI

To begin monitoring, control room operators turn on the IrMonitor system and a server on the plant’s Ethernet-based LAN sends an identification number in a proprietary “data telegram” file format developed by the ArcelorMittal steel plant to the vision PC. The IrMonitor software running on the vision PC then begins searching each frame of transmitted digital video from each of the four A320G cameras for a matching shape similar to a stored template on the PC.

When IrMonitor finds a template match, it draws a region of interest around the ladle to exclude temperature values from nearby pipes, ovens, or other equipment that might operate at high temperatures and trigger a false alarm. This step also allows the vision system to monitor ladle temperatures without requiring the crane operator to stop at a particular point while the vision system acquires an image.

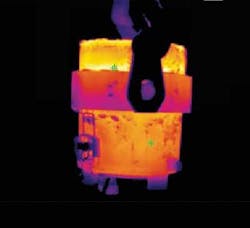

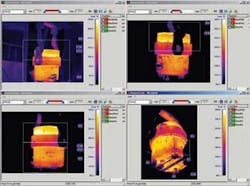

Once the template match comes back positive and the ROI mask is overlaid, IrMonitor uses the temperature values for each pixel within the region of interest to determine whether any point on the ladle is exceeding 400°C (see Fig. 4).

FIGURE 4. The IrMonitor software can automatically control gimbals for pan/tilt/scan systems when fixed cameras will not meet application requirements.

“The exact temperature threshold is based on the customer’s experience,” explains Automation Technologies’ Wandelt. “In this case, we’re on the safe side until the temperature reaches 400°C. If we exceed that temperature, IrMonitor sends an alarm telegram to the control center, showing the image on the system’s only display with regions of high temperature highlighted, as well as the ladle ID number and historical temperatures for that ladle. If the temperature exceeds 500°C, an alarm message is sent to the control room and the crane operator for an emergency stop.”

As a fail-safe measure to ensure that each camera is operating correctly and that the factory-set calibration has not drifted, Automation Technology installed a blackbody source within each camera’s field of view. “The blackbodies stay at a constant temperature of 70°C,” says Wandelt. “During each ladle measurement, we check the temperature of the blackbody source. If this reference temperature deviates too much, then we alert the control room via alarm telegram that there may be dust over the enclosure window, a faulty blackbody source, or a faulty camera.”

The torpedo car vision system is very similar to the ladle inspection system except that it only uses two A320G IR cameras with wide-angle lenses on each side of the larger torpedo cars, and a Basler scout scA640 monochrome camera to read the ID number posted on the side of the railcar. The OCR software for reading the ID numbers is based on National Instruments Vision Builder image-processing software (see Fig. 5).

FIGURE 5. Unlike the ladle vision system that receives ladle identification numbers from a plant server, the torpedo car vision system use a monochrome camera to read ID plaques located on the side of the torpedo car. This ID number is saved along with the IR image of the torpedo car and temperature readings from the software.

null

Automated asset management

In addition to providing safety alarms for containers that pose a danger to employees and operations, IrMonitor comes with a built-in database to store temperature readings and photos for each vessel over time.

“If you have 100 measurements for one ladle over time, then you can see what the temperature development has been and estimate how long you can continue to reuse the ladle before renewing the refractory material,” explains Wandelt. The IrMonitor database comes with ODBC and OPC-Server capability for remote connection, control, and automated data transfer to remote applications.

The ability to network multiple IR cameras in an industrial plant setting makes IrMonitor a tool for any application where temperature is a critical factor, according to Markus Tarin, president of MoviMED, the US distributor and integrator for Automation Technology. Other examples are predictive maintenance applications for monitoring electrical and mechanical equipment, critical vessel monitoring in chemical and petrochemical plants, high-value residential and commercial property surveillance, and perimeter security for dangerous workplaces. Tarin adds that IrMonitor allows particular regions of interest to be associated with a particular pan and tilt angle, therefore mimicking a multicamera setup.

Company Info

AT-Automation Technology

Trittau, Germany

www.automationtechnology.de

Basler, Ahrensburg, Germany

www.baslerweb.com

FLIR Systems

North Billerica, MA, USA

www.flir.com

Microsens, Hamm, Germany

www.microsens.de

MoviMED

Irvine, CA, USA

www.movimed.com

National Instrument

Austin, TX, USA

www.ni.com